Abstract

In recent days, cheapest alternative carbon source for fermentation purpose is desirable to minimize production cost. Xylanases have become attractive enzymes as their potential in bio-bleaching of pulp and paper industry. The objective of the present study was to identify the potential ability on the xylanase production by locally isolated Bacillus pumilus BS131 by using waste fiber sludge and wheat bran media under submerged fermentation. Culture growth conditions were optimized to obtain significant amount of xylanase. Maximum xylanase production was recorded after 72 hours of incubation at 30 °C and 7 pH with 4.0% substrate concentration. In the nutshell, the production of xylanase using inexpensive waste fiber sludge and wheat-bran as an alternative in place of expensive xylan substrate was more cost effective and environment friendly.

Keywords:

waste fiber sludge; xylanase; fermentation; enzyme production; submerged fermentation; Bacillus pumilus

Resumo

Nos últimos dias, a fonte alternativa de carbono mais barata para fins de fermentação é desejável para minimizar o custo de produção. As xilanases têm se tornado enzimas atraentes como seu potencial no biobranqueamento da indústria de papel e celulose. O objetivo do presente estudo foi identificar a capacidade potencial na produção de xilanase por Bacillus pumilus BS131 isolado localmente usando lodo de fibra residual e farelo de trigo em meio de fermentação submersa. As condições de crescimento da cultura foram otimizadas para obter uma quantidade significativa de xilanase. A produção máxima de xilanase foi registrada após 72 horas de incubação a 30 °C e pH 7 com concentração de substrato de 4,0%. Resumindo, a produção de xilanase usando lodo de fibra residual de baixo custo e farelo de trigo como uma alternativa no lugar do substrato de xilano caro foi mais econômica e ecológica.

Palavras-chave:

resíduos de lodo de fibra; xilanase; fermentação; produção de enzimas; fermentação submersa; Bacillus pumilus

1. Introduction

Agro-industrial waste is among the major environmental pollutants. Their microbial conversion is not only a solution to many environmental problems but also a source of suitable byproducts like food, fuel and chemicals (Milala et al., 2005MILALA, M.A., SHUGABA, A., GIDADO, A., ENE, A.C. and WAFAR, J.A., 2005. Studies on the use of agricultural wastes for cellulase enzyme production by A. Niger. Research Journal of Agriculture and Biological Sciences, vol. 1, no. 4, pp. 325-328.). Wheat bran is one of the most abundant agricultural wastes of Pakistan food industries whereas fiber sludge is paper industry waste of no value. Microbial xylanases from high yielding strains of Aeromonas, Agrobacterium, Bacillus, Dictyoglomus, Nocardia, Pseudomonas, Thermotoga and Xanthomonas are grown under submerged fermentation conditions (SmF). The Bacilli are found to be the most important group of bacteria which are actively used in enzyme industry and are reported to produce hydrolytic enzymes quite significantly (Bastawde, 1992BASTAWDE, K.B., 1992. Xylan structure, microbial xylanases and their mode of action. World Journal of Microbiology & Biotechnology, vol. 8, no. 4, pp. 353-368. http://dx.doi.org/10.1007/BF01198746. PMid:24425504.

http://dx.doi.org/10.1007/BF01198746...

). Studies have shown that some nutritional factors including the sources of carbon and nitrogen can influence the production of xylanase enzyme (Farjalla et al., 2006FARJALLA, V.F., ENRICH-PRAST, A., ESTEVES, F.A. and CIMBLERIS, A.C.P., 2006. Bacterial growth and DOC consumption in a tropical coastal lagoon. Brazilian Journal of Biology = Revista Brasileira de Biologia, vol. 66, no. 2a, pp. 383-392.). Besides this, some physical factors such as time course study, temperature, pH, substrate concentration can significantly affect the production of xylanase (Bhardwaj et al., 2017BHARDWAJ, N., CHANDA, K., KUMAR, B., PRASAD, H., SHARMA, G.D. and VERMA, P., 2017. Statistical optimization of nutritional and physical parameters for xylanase production from newly isolated Aspergillus oryzae LC1 and its application in the hydrolysis of lignocellulosic agro-residues. BioResources, vol. 12, no. 4, pp. 8519-8538.).

This particular study was aimed at growth optimization of Bacillus pumilus strain BS131 isolated from agricultural soil to enhance the xylanase enzyme production using waste fiber sludge and wheat bran as carbon source.

2. Materials and Methods

2.1. Selection of substrates

Waste fiber sludge was obtained from Bulleh Shah Packaging, Kasure, Pakistan and wheat bran was collected from local wheat processors, Lahore, Pakistan. These solid wastes were used as substrate for xylanase production under submerged fermentation conditions.

2.2. Bacterial strain

Bacillus pumilus BS131 was locally isolated from soil as previously mentioned (Kalim and Ali, 2016Kalim, B and Ali, N. M., 2016. Optimization of fermentation media and growth conditions for microbial xylanase production. 3Biotech. vol. 6, no. 2, p. 122.). This strain was maintained on nutrient agar slants and stored at 4 °C.

2.3. Cultivation of bacterial cells

Twenty five milliliters of sterilized nutrient broth were inoculated with a loopful of 24 h old culture of Bacillus pumilus BS131 and incubated overnight at 37 °C, 120 rpm agitation. Vegetative cells were used as a source of inoculum throughout the study.

2.4. Fermentation technique

Fifty milliliters of fermentation media (g/L: Glucose 20, KH2PO4 5.0, MgSO4.7H2O 0.2, NH4NO3 2.0, (NH4)2SO4 4.0, Trisodium citrate 5.0 and Yeast extract 1.0.) with 2% substrate (Waste fiber sludge and Wheat bran 1:1) were sterilized in each 250 ml Erlenmeyer flask. After sterilization, the media was inoculated with 2% solution containing vegetative cells of 24 h old B. pumilus BS131 in each flask and incubated in refrigerated shaking incubator (TSS-40-250, Technico scientific supply, Lahore, Pakistan) at 30 °C for 5 days with an agitation speed of 120 rpm.

2.5. Preparation of enzyme

After incubation, the fermented broth was filtered through 0.45µm micro-filter membranes and finally by centrifugation at 4 °C, 6,708 g for 20 min to remove the bacterial cells and undesired particles. Clear filtrate was collected after centrifugation and was used as a source of crude enzyme.

2.6. Assay of xylanase enzyme

Xylanase enzyme in the culture filtrate was estimated as reported earlier (Kalim and Ali, 2016Kalim, B and Ali, N. M., 2016. Optimization of fermentation media and growth conditions for microbial xylanase production. 3Biotech. vol. 6, no. 2, p. 122.). Reaction mixture containing 0.5 mL of each of the appropriately diluted culture filtrate and 1% birchwood xylan (Sigma) solution prepared in 0.05 M citrate buffer (pH 5.5) was incubated for at 50 °C. After 15 min the reaction was terminated by the addition of 2.0 mL of 3,5-dinitrosalicylic acid (DNS) and incubating in a boiling water-bath for 10 min (Bailey et al., 1992BAILEY, M.J., BIELY, P. and POUTANEN, K., 1992. Interlaboratory testing of methods for assay of xylanase activity. Journal of Biotechnology, vol. 23, no. 3, pp. 257-270. http://dx.doi.org/10.1016/0168-1656(92)90074-J.

http://dx.doi.org/10.1016/0168-1656(92)9...

). Reducing sugars liberated were measured by spectrophotometer at 553 nm and expressed as xylose equivalent. One unit enzyme activity was defined as the amount of enzyme required to produce 1 mM reducing sugar as a xylose equivalent per minute under standard assay conditions. Units were calculated by using following Formula 1.

Where,

ΔE = Absorbance at 553 nm

Vf = Final volume of reaction mixture (enzyme + substrate + DNS)

MW = Molecular weight of xylose/glucose

ΔT = incubation period in minutes

Df = Dilution factor

2.7. Optimization of cultural and nutritional conditions for xylanase production

The various cultural conditions including time course of fermentation (12-120 hours), incubation temperature (20-45 °C), initial medium pH (3-9), substrate concentration (2-10%) and different nutritional conditions including additional carbon sources (CMC, corncobs, rice straw, wheat bran, xylan and xylose) and nitrogen sources (beef extract, urea, yeast extract and peptone) were optimized for enhanced production of xylanase by the tested strain of B. pumilus BS131 in SmF process.

2.8. Effect of cultivation period on production of xylanase

Sterilized fermentation medium with 2% waste fiber sludge and wheat bran (pH 5.5) was inoculated with B. pumilus BS131 and incubated in a shaking incubator at 30 °C. Production of xylanase was monitored under sterilized conditions. One mL of culture medium was withdrawn after every 24 hours and DNS assay was performed for the quantification of xylanase. Enzyme production was observed every 24 h for 5 days. Xylanase activity was calculated in IU/mL.

2.9. Effect of temperature on production of xylanase

Temperature effect on the production of xylanase was estimated by incubating fermentation media with 2% substrate (untreated waste fiber sludge and wheat bran; 1:1) at pH 5.5 and temperatures between 20 and 45 °C with a regular interval of 5 °C. The activity of the enzyme was determined using DNS assay within the preset temperature range.

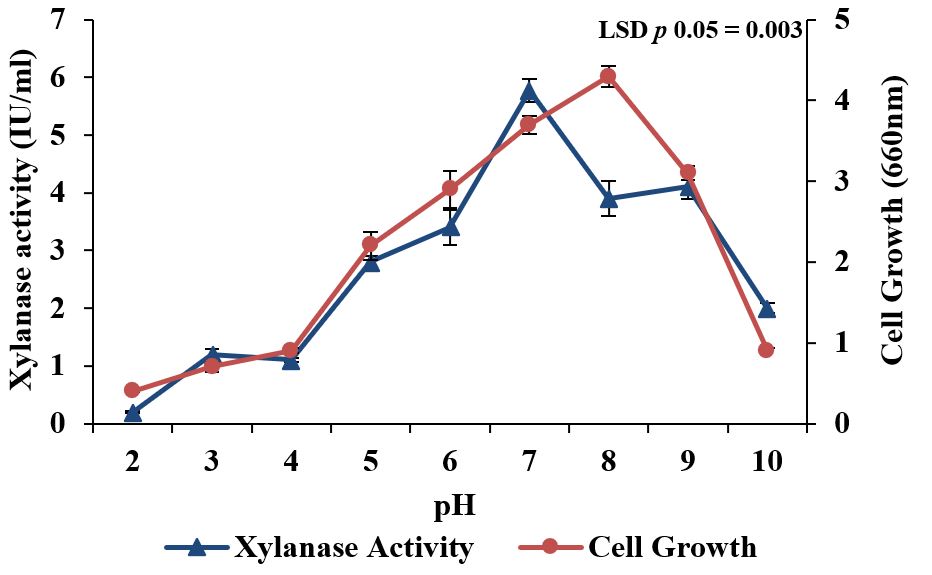

2.10. Effect of pH on production of xylanase

The initial pH for the production of enzyme was determined by incubating fermentation medium with 2% substrate having different pH values set at acidic to alkaline pH i.e. 3.0, 5.0, 7.0 and 9.0 while using micro filtered solutions of 1M NaOH and 1M Tartaric Acid. Fermentation media was incubated for 72 h at 30 °C. After incubation the xylanase activity was determined using DNS assay and absorbance was measured at 553 nm.

2.11. Effect of substrate concentration

Effect of substrate concentration was determined by using different concentrations of waste fiber sludge and wheat bran (1:1) in fermentation media i.e. 1.0-6.0%. In 250 mL flasks, 50 mL of fermentation media was autoclaved and inoculated under aseptic conditions. All the samples were incubated at 30 °C. Afterwards, cell free culture filtrate (CFCF) was obtained for the estimation of xylanase production by using DNS assay.

2.12. Effect of carbon and nitrogen sources on xylanase production

Effect of different carbon and nitrogen sources on xylanase production was observed. Different carbon sources (carboxymethyl cellulose (CMC), corncobs, rice straw, wheat bran, xylan and xylose) and nitrogen sources (beef extract, peptone, urea and yeast extract) were experimented for their effect on xylanase production. Thirty mL of fermentation media supplemented with 0.5% of each of the carbon and nitrogen sources was autoclaved incubated at 30 °C. Release of xylose subunits was estimated by comparing optical density with xylose standard curve and enzyme activity was calculated using appropriate formula. Production of extracellular xylanase was estimated under the effect of nitrogen sources using DNS assay.

2.13. Statistical analysis

The data obtained after experimentation was statistically evaluated using ANOVA Dunken’s New Multiple Range Test (DNMRT) at significance level of p < 0.05 by using computer based program DSA STAT (Onofri, Italy).

3. Results and Discussion

3.1. Time course study for xylanase production

Ten experiments with an interval of twelve hours each were performed to study the optimum period for maximum production of xylanase under SmF process. Figure 1 describes that xylanase production was maximum after 72 h of fermentation at 30 °C for B. pumilus BS131. Further increase of fermentation period resulted in a decline of enzyme production which might be due to the production of some toxic metabolites during microbial growth which inhibits the enzyme synthesis. Yang et al. (1995)YANG, V.W., ZHUANG, Z., ELEGIR, G. and JEFFRIES, T.W., 1995. Alkaline active xylanase produced by an alkallophilic Bacillus sp. isolated from kraft pulp. Journal of Industrial Microbiology & Biotechnology, vol. 15, no. 5, pp. 434-441. http://dx.doi.org/10.1007/BF01569971.

http://dx.doi.org/10.1007/BF01569971...

studied xylanase production by Bacillus sp. and reported maximum xylanase production in 72 h using wheat bran as a substrate. Xue et al. (2012)XUE, H., ZHOU, J., YOU, C., HUANG, Q. and LU, H., 2012. Amino acid substitutions in the N-terminus, cord and α-helix domain improved the thermostability of a family 11 xylanase XynR8. Journal of Industrial Microbiology & Biotechnology, vol. 39, no. 9, pp. 1279-1288. http://dx.doi.org/10.1007/s10295-012-1140-y. PMid:22584821.

http://dx.doi.org/10.1007/s10295-012-114...

reported 27 h of fermentation time for maximum production of xylanase from Bacillus pumilus strain. Kumar and Satyanarayana (2014)KUMAR, V. and SATYANARAYANA, T., 2014. Production of thermo-alkali-stable xylanase by a novel polyextremophilic Bacillus halodurans TSEV1 in cane molasses medium and its applicability in making whole wheat bread. Bioprocess and Biosystems Engineering, vol. 37, no. 6, pp. 1043-1053. http://dx.doi.org/10.1007/s00449-013-1075-3. PMid:24297158.

http://dx.doi.org/10.1007/s00449-013-107...

reported 56 h of fermentation period was optimum for xylanase production by an alkaliphilic Bacillus pumilus VLK-1 in SmF using wheat bran as a substrate. In another study a Bacillus pumilus strain showed maximum xylanase production after 20 h using birchwood xylan (Duarte et al., 1999DUARTE, M.C.T., PORTUGAL, E.P., PONEZI, A., BIM, M.A., TAGLIARI, C.V. and FRANCO, T.T, 1999. Production and purification of alkaline xylanases. Bioresource Technology, vol. 68, no. 1, pp. 49-53. http://dx.doi.org/10.1016/S0960-8524(98)00079-0.

http://dx.doi.org/10.1016/S0960-8524(98)...

). Kapilan and Arasaratnam (2012)KAPILAN, R. and ARASARATNAM, V., 2012. Comparison of the kinetic properties of crude and purified xylanase from Bacillus pumilus with commercial xylanase from Aspergillus niger. Ving Journal Science, vol. 10, no. 1, pp. 1-6. http://dx.doi.org/10.4038/vingnanam.v10i1.4072.

http://dx.doi.org/10.4038/vingnanam.v10i...

isolated B. subtilis from soil which exhibit highest xylanase activity after 42 h in SmF.

Effect of incubation period on cell growth and xylanase production by Bacillus pumilus strain BS131.

3.2. Effect of incubation temperature on xylanase production

For the maximum production of xylanase enzyme, BS131 was incubated at different temperature ranges (20-45 °C) were tested. Figure 2 illustrates that, at 25 °C bacterial strains did not grow well thus resulting in decreased enzyme production. B. pumilus BS131 produced maximum titer of xylanase (6.409 ± 0.17 IU/mL) at 30 °C. Increase in incubation temperature up to 45 °C significantly reduced enzyme production. Banu and Ingale (2012)BANU, A. and INGALE, S., 2012. Xylanase production by Bacillus pumilus AB-1 under solid state fermentation and its application. Bulletin of Environmental and Scientific Research, vol. 1, no. 1, pp. 35-43. reported the maximum production of xylanase by B. pumilus strain AB-1 at 30 °C. Thomas et al., (2014)THOMAS, L., USHASREE, M.V. and PANDEY, A., 2014. An alkali-thermostable xylanase from Bacillus pumilus functionally expressed in Kluyveromyces lactis and evaluation of its deinking efficiency. Bioresource Technology, vol. 165, pp. 309-313. http://dx.doi.org/10.1016/j.biortech.2014.03.037. PMid:24709528.

http://dx.doi.org/10.1016/j.biortech.201...

reported optimum temperature of 33.5 °C for the production of xylanase by B. pumilus MTCC 5015 in submerged fermentation. Different strains of Bacillus sp. gave maximum yield of xylanase production at incubation temperature of 45 °C and 55 °C (Buthelezi et al., 2011BUTHELEZI, S.P., OLANIRAN, A.O. and PILLAY, B., 2011. Sawdust and digestive bran as cheap alternate substrates for xylanase production. African Journal of Microbiological Research, vol. 5, no. 7, pp. 742-752. http://dx.doi.org/10.5897/AJMR10.366.

http://dx.doi.org/10.5897/AJMR10.366...

). Xue et al. (2012)XUE, H., ZHOU, J., YOU, C., HUANG, Q. and LU, H., 2012. Amino acid substitutions in the N-terminus, cord and α-helix domain improved the thermostability of a family 11 xylanase XynR8. Journal of Industrial Microbiology & Biotechnology, vol. 39, no. 9, pp. 1279-1288. http://dx.doi.org/10.1007/s10295-012-1140-y. PMid:22584821.

http://dx.doi.org/10.1007/s10295-012-114...

reported the incubation at 45 °C gave maximum xylanase production by B. pumilus.

Effect of temperature on cell growth and xylanase production by Bacillus pumilus strain BS131.

3.3. Effect of initial medium pH for xylanase production

Most of bacterial strains are dependent on pH and produce xylanase under neutral to high pH (Nakamura et al., 1994NAKAMURA, S., NAKAI, R., WAKABAYASHI, K., ISHIGURO, Y., AONO, R. and HORIKOSHI, K., 1994. Thermophilic alkaline xylanase from newly isolated alkaliphilic and thermophilic Bacillus sp. strain TAR1. Bioscience, Biotechnology, and Biochemistry, vol. 58, no. 1, pp. 78-81. http://dx.doi.org/10.1271/bbb.58.78. PMid:27315708.

http://dx.doi.org/10.1271/bbb.58.78...

; Ratanachomsri et al., 2006RATANACHOMSRI, U., SRIPRANG, R., SORNLEK, W., BUABAN, B., CHAMPREDA, V., TANAPONGPIPAT, S. and EURWILAICHITR, L., 2006. Thermostable xylanase from Marasmius sp.: purification and characterization. Journal of Biochemistry and Molecular Biology, vol. 39, no. 1, pp. 105-110. PMid:16475280.). The pH of the growth medium strongly affects many enzymatic processes and transport of various components across the cell membrane (Kapoor et al., 2008KAPOOR, M., NAIR, L.M. and KUHAD, R.C., 2008. Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochemical Engineering Journal, vol. 38, no. 1, pp. 88-97. http://dx.doi.org/10.1016/j.bej.2007.06.009.

http://dx.doi.org/10.1016/j.bej.2007.06....

). Different pH ranges (3.0-10.0) were tested for maximum xylanase production by B. pumilus BS131 in submerged fermentation. Figure 3 reveals that the bacterial strain exhibited its peak activity at pH 7.0. Very Low pH (3.0) and high pH (10.0) of the medium retards xylanase secretion. These results indicated that B. pumilus BS131 showed maximum xylanase production at neutral pH but can tolerate alkaline conditions. Identical results were recorded by Kumar and Satyanarayana (2014)KUMAR, V. and SATYANARAYANA, T., 2014. Production of thermo-alkali-stable xylanase by a novel polyextremophilic Bacillus halodurans TSEV1 in cane molasses medium and its applicability in making whole wheat bread. Bioprocess and Biosystems Engineering, vol. 37, no. 6, pp. 1043-1053. http://dx.doi.org/10.1007/s00449-013-1075-3. PMid:24297158.

http://dx.doi.org/10.1007/s00449-013-107...

showing optimum pH of 7.0 for xylanase production by B. pumilus strain VLK-1 in submerged fermentation. Bacillus pumilus strain MTCC 5015 showed maximum xylanase production at pH 9.0 under submerged fermentation (Thomas et al., 2014THOMAS, L., USHASREE, M.V. and PANDEY, A., 2014. An alkali-thermostable xylanase from Bacillus pumilus functionally expressed in Kluyveromyces lactis and evaluation of its deinking efficiency. Bioresource Technology, vol. 165, pp. 309-313. http://dx.doi.org/10.1016/j.biortech.2014.03.037. PMid:24709528.

http://dx.doi.org/10.1016/j.biortech.201...

).

3.4. Effect of substrate concentration on xylanase production

Figure 4 describes the production of xylanase by Bacillus pumilus BS131 under submerged fermentation conditions using different concentrations of carbon source (1.0-6.0%). Results indicated that the strain BS131 showed its peak production (6.73 ± 0.98 IU/ml) with 4% substrate concentration (waste fiber sludge and wheat bran; 1:1). Further increase in substrate concentration did not significantly affect the enzyme production. Kuhad et al. (1998)KUHAD, R.C., MANCHANDA, M. and SINGH, A., 1998. Optimization of xylanase production by a hyperxylanolytic mutant strain of Fusarium oxysporu. Process Biochemistry, vol. 33, no. 6, pp. 641-647. http://dx.doi.org/10.1016/S0032-9592(98)00025-9.

http://dx.doi.org/10.1016/S0032-9592(98)...

reported that the maximum amount of xylanase was produced at 4% concentration of wheat bran. Cavka et al. (2011)CAVKA, A., ALRIKSSON, B., AHNLUND, M. and JÖNSSON, L.J., 2011. Effect of sulfur oxyanions on lignocellulose-derived fermentation inhibitors. Biotechnology and Bioengineering, vol. 108, no. 11, pp. 2592-2599. http://dx.doi.org/10.1002/bit.23244. PMid:21702027.

http://dx.doi.org/10.1002/bit.23244...

used waste fiber sludge for combined production of ethanol and xylanase. Irfan et al. (2012)IRFAN, M., NADEEM, M., SYED, Q. and BAIG, S., 2012. Effect of medium composition on xylanase production by Bacillus subtilis using various agricultural wastes. American-Eurasian Journal of Agricultural & Environmental Sciences, vol. 12, no. 5, pp. 561-565. produced xylanase from B. subtilis BS05 using different agricultural wastes as a substrate in submerge fermentation and observed maximum xylanase activity in 2% sugarcane bagasse. Ho (2015)HO, H.L., 2015. Xylanase production by Bacillus subtilis using carbon source of inexpensive agricultural wastes in two different approaches of submerged fermentation (SmF) and solid state fermentation (SSF). Journal of Food Processing and Technology, vol. 6, no. 4, p. 437. produced xylanases from Bacillus subtilus using inexpensive agricultural wastes and reported higher xylanase activity while using barley husk under submerged fermentation and wheat bran in solid state fermentation. Li et al. (2006)LI, Y., LIN, J., MENG, D., LU, J. and GU, G., 2006. Effect of pH, cultivation time and substrate concentration on the endoxylanase production by Aspergillus awamoriZH-26 under submerged fermentation using central composite rotary design. Food Technology and Biotechnology, vol. 44, no. 4, pp. 473-477. produced Aspergillus awamori ZH-26 endoxylanase under submerged fermentation and reported wheat bran (4.93%) best for endoxylanase production.

Effect of substrate concentration on cell growth and xylanase production by Bacillus pumilus strain BS131.

3.5. Effect of additional carbon and nitrogen sources on xylanase production

Production of xylanase was further enhanced by supplementing the fermentation medium with suitable additional carbon and nitrogen sources. Figure 5 depicts that xylan followed by wheat bran were the best xylanase inducer by B. pumilus BS131 in submerged fermentation. For other carbon sources xylanase production decreased in the sequence of xylose>wheat-bran>corncob>rice straw>CMC. Rani and Nand (2000)RANI, D.S. and NAND, K., 2000. Production of thermostable cellulase-free xylanase by Clostridium absonum CFR-702. Process Biochemistry, vol. 36, no. 4, pp. 355-362. http://dx.doi.org/10.1016/S0032-9592(00)00224-7.

http://dx.doi.org/10.1016/S0032-9592(00)...

reported that maximum amount of xylanase was produced in corn cobs (3%) when anaerobic bacterium Clostridium absonum CFR-702. Jorgensen et al. (2003)JØRGENSEN, H., ERIKSSON, T., BÖRJESSON, J., TJERNELD, F. and OLSSON, L., 2003. Purification and characterization of five cellulases and one xylanase from Penicillium brasilianum IBT 20888. Enzyme and Microbial Technology, vol. 32, no. 7, pp. 851-861. http://dx.doi.org/10.1016/S0141-0229(03)00056-5.

http://dx.doi.org/10.1016/S0141-0229(03)...

reported that xylose is a less repressing sugar and cultivation on xylose revealed detectable amounts of xylanase in Penicillium sp. as was seen in the present study. Azeri et al. (2010)AZERI, C., TAMER, A.U. and OSKAY, A., 2010. Thermoactive cellulase-free xylanase production from alkaliphilic Bacillus strains using various agro-residues and their potential in biobleaching of kraft pulp. African Journal of Biotechnology, vol. 9, no. 1, pp. 63-72. produced extracellular xylanase from Bacilli and reported maximum xylanolytic activity by using birchwood xylan as a carbon source followed by wheat straw and wheat bran.

Effect of carbon source on xylanase production by Bacillus pumilus strain BS131.*Less significant,**significant,***highly significant.

Peptone and yeast extract were observed to be the best suited organic nitrogen sources for xylanase synthesis under submerged fermentation by B. pumilus BS131 (Figure 6). The production of xylanolytic enzymes by fungi shows a dramatic significance with an addition of nitrogen sources, also the organic sources of nitrogen were observed to be more signifant than inorganic ones for Chaetomium cellulolyticum (Dubeau et al., 1987DUBEAU, H., CHAHAL, D.S. and ISHAQUE, M., 1987. Xylanase of Chaetomium cellulolytium; its nature of production and hydrolysis potential. Biotechnology Letters, vol. 9, no. 4, pp. 275-287. http://dx.doi.org/10.1007/BF01027163.

http://dx.doi.org/10.1007/BF01027163...

), Aspergillus awamori (Smith and Wood, 1991SMITH, D.C. and WOOD, T.M., 1991. Xylanase production by Aspergillus awamorri Development of a medium and optimisation of extracellular xylanase and β- xylosidases while maintaining low protease production. Biotechnology and Bioengineering, vol. 38, no. 8, pp. 883-890. http://dx.doi.org/10.1002/bit.260380810. PMid:18600845.

http://dx.doi.org/10.1002/bit.260380810...

), Fusarium oxysporum (Kuhad et al., 1998KUHAD, R.C., MANCHANDA, M. and SINGH, A., 1998. Optimization of xylanase production by a hyperxylanolytic mutant strain of Fusarium oxysporu. Process Biochemistry, vol. 33, no. 6, pp. 641-647. http://dx.doi.org/10.1016/S0032-9592(98)00025-9.

http://dx.doi.org/10.1016/S0032-9592(98)...

). Banu and Ingale (2012)BANU, A. and INGALE, S., 2012. Xylanase production by Bacillus pumilus AB-1 under solid state fermentation and its application. Bulletin of Environmental and Scientific Research, vol. 1, no. 1, pp. 35-43. reported that yeast extract have been successfully used in Bacillus pumilus as a relatively cheaper complex N-source.

Effect of nitrogen source on xylanase production by Bacillus pumilus strain BS131. *Less significant,**significant,***highly significant.

4. Conclusion

The results of this study revealed that Bacillus pumilus BS131 can produce xylanase enzyme using waste fiber sludge and wheat bran as substrate in submerged fermentation which was not reported earlier. In this study bacterial strain was used for xylanase enzyme production which has advantage of short period of growth as compared to the fungi. Results of the present study indicated the pivotal role of nutrients and cultural properties played in enzyme production under submerged fermentation conditions. The optimization of all the process parameters are being considered as prerequisites to make the process of enzyme production cost effective at large scale.

References

- AZERI, C., TAMER, A.U. and OSKAY, A., 2010. Thermoactive cellulase-free xylanase production from alkaliphilic Bacillus strains using various agro-residues and their potential in biobleaching of kraft pulp. African Journal of Biotechnology, vol. 9, no. 1, pp. 63-72.

- BAILEY, M.J., BIELY, P. and POUTANEN, K., 1992. Interlaboratory testing of methods for assay of xylanase activity. Journal of Biotechnology, vol. 23, no. 3, pp. 257-270. http://dx.doi.org/10.1016/0168-1656(92)90074-J

» http://dx.doi.org/10.1016/0168-1656(92)90074-J - BANU, A. and INGALE, S., 2012. Xylanase production by Bacillus pumilus AB-1 under solid state fermentation and its application. Bulletin of Environmental and Scientific Research, vol. 1, no. 1, pp. 35-43.

- BASTAWDE, K.B., 1992. Xylan structure, microbial xylanases and their mode of action. World Journal of Microbiology & Biotechnology, vol. 8, no. 4, pp. 353-368. http://dx.doi.org/10.1007/BF01198746 PMid:24425504.

» http://dx.doi.org/10.1007/BF01198746 - BHARDWAJ, N., CHANDA, K., KUMAR, B., PRASAD, H., SHARMA, G.D. and VERMA, P., 2017. Statistical optimization of nutritional and physical parameters for xylanase production from newly isolated Aspergillus oryzae LC1 and its application in the hydrolysis of lignocellulosic agro-residues. BioResources, vol. 12, no. 4, pp. 8519-8538.

- BUTHELEZI, S.P., OLANIRAN, A.O. and PILLAY, B., 2011. Sawdust and digestive bran as cheap alternate substrates for xylanase production. African Journal of Microbiological Research, vol. 5, no. 7, pp. 742-752. http://dx.doi.org/10.5897/AJMR10.366

» http://dx.doi.org/10.5897/AJMR10.366 - CAVKA, A., ALRIKSSON, B., AHNLUND, M. and JÖNSSON, L.J., 2011. Effect of sulfur oxyanions on lignocellulose-derived fermentation inhibitors. Biotechnology and Bioengineering, vol. 108, no. 11, pp. 2592-2599. http://dx.doi.org/10.1002/bit.23244 PMid:21702027.

» http://dx.doi.org/10.1002/bit.23244 - DUARTE, M.C.T., PORTUGAL, E.P., PONEZI, A., BIM, M.A., TAGLIARI, C.V. and FRANCO, T.T, 1999. Production and purification of alkaline xylanases. Bioresource Technology, vol. 68, no. 1, pp. 49-53. http://dx.doi.org/10.1016/S0960-8524(98)00079-0

» http://dx.doi.org/10.1016/S0960-8524(98)00079-0 - DUBEAU, H., CHAHAL, D.S. and ISHAQUE, M., 1987. Xylanase of Chaetomium cellulolytium; its nature of production and hydrolysis potential. Biotechnology Letters, vol. 9, no. 4, pp. 275-287. http://dx.doi.org/10.1007/BF01027163

» http://dx.doi.org/10.1007/BF01027163 - FARJALLA, V.F., ENRICH-PRAST, A., ESTEVES, F.A. and CIMBLERIS, A.C.P., 2006. Bacterial growth and DOC consumption in a tropical coastal lagoon. Brazilian Journal of Biology = Revista Brasileira de Biologia, vol. 66, no. 2a, pp. 383-392.

- HO, H.L., 2015. Xylanase production by Bacillus subtilis using carbon source of inexpensive agricultural wastes in two different approaches of submerged fermentation (SmF) and solid state fermentation (SSF). Journal of Food Processing and Technology, vol. 6, no. 4, p. 437.

- IRFAN, M., NADEEM, M., SYED, Q. and BAIG, S., 2012. Effect of medium composition on xylanase production by Bacillus subtilis using various agricultural wastes. American-Eurasian Journal of Agricultural & Environmental Sciences, vol. 12, no. 5, pp. 561-565.

- JØRGENSEN, H., ERIKSSON, T., BÖRJESSON, J., TJERNELD, F. and OLSSON, L., 2003. Purification and characterization of five cellulases and one xylanase from Penicillium brasilianum IBT 20888. Enzyme and Microbial Technology, vol. 32, no. 7, pp. 851-861. http://dx.doi.org/10.1016/S0141-0229(03)00056-5

» http://dx.doi.org/10.1016/S0141-0229(03)00056-5 - Kalim, B and Ali, N. M., 2016. Optimization of fermentation media and growth conditions for microbial xylanase production. 3Biotech vol. 6, no. 2, p. 122.

- KAPILAN, R. and ARASARATNAM, V., 2012. Comparison of the kinetic properties of crude and purified xylanase from Bacillus pumilus with commercial xylanase from Aspergillus niger. Ving Journal Science, vol. 10, no. 1, pp. 1-6. http://dx.doi.org/10.4038/vingnanam.v10i1.4072

» http://dx.doi.org/10.4038/vingnanam.v10i1.4072 - KAPOOR, M., NAIR, L.M. and KUHAD, R.C., 2008. Cost-effective xylanase production from free and immobilized Bacillus pumilus strain MK001 and its application in saccharification of Prosopis juliflora. Biochemical Engineering Journal, vol. 38, no. 1, pp. 88-97. http://dx.doi.org/10.1016/j.bej.2007.06.009

» http://dx.doi.org/10.1016/j.bej.2007.06.009 - KUHAD, R.C., MANCHANDA, M. and SINGH, A., 1998. Optimization of xylanase production by a hyperxylanolytic mutant strain of Fusarium oxysporu. Process Biochemistry, vol. 33, no. 6, pp. 641-647. http://dx.doi.org/10.1016/S0032-9592(98)00025-9

» http://dx.doi.org/10.1016/S0032-9592(98)00025-9 - KUMAR, V. and SATYANARAYANA, T., 2014. Production of thermo-alkali-stable xylanase by a novel polyextremophilic Bacillus halodurans TSEV1 in cane molasses medium and its applicability in making whole wheat bread. Bioprocess and Biosystems Engineering, vol. 37, no. 6, pp. 1043-1053. http://dx.doi.org/10.1007/s00449-013-1075-3 PMid:24297158.

» http://dx.doi.org/10.1007/s00449-013-1075-3 - LI, Y., LIN, J., MENG, D., LU, J. and GU, G., 2006. Effect of pH, cultivation time and substrate concentration on the endoxylanase production by Aspergillus awamoriZH-26 under submerged fermentation using central composite rotary design. Food Technology and Biotechnology, vol. 44, no. 4, pp. 473-477.

- MILALA, M.A., SHUGABA, A., GIDADO, A., ENE, A.C. and WAFAR, J.A., 2005. Studies on the use of agricultural wastes for cellulase enzyme production by A. Niger. Research Journal of Agriculture and Biological Sciences, vol. 1, no. 4, pp. 325-328.

- NAKAMURA, S., NAKAI, R., WAKABAYASHI, K., ISHIGURO, Y., AONO, R. and HORIKOSHI, K., 1994. Thermophilic alkaline xylanase from newly isolated alkaliphilic and thermophilic Bacillus sp. strain TAR1. Bioscience, Biotechnology, and Biochemistry, vol. 58, no. 1, pp. 78-81. http://dx.doi.org/10.1271/bbb.58.78 PMid:27315708.

» http://dx.doi.org/10.1271/bbb.58.78 - RANI, D.S. and NAND, K., 2000. Production of thermostable cellulase-free xylanase by Clostridium absonum CFR-702. Process Biochemistry, vol. 36, no. 4, pp. 355-362. http://dx.doi.org/10.1016/S0032-9592(00)00224-7

» http://dx.doi.org/10.1016/S0032-9592(00)00224-7 - RATANACHOMSRI, U., SRIPRANG, R., SORNLEK, W., BUABAN, B., CHAMPREDA, V., TANAPONGPIPAT, S. and EURWILAICHITR, L., 2006. Thermostable xylanase from Marasmius sp.: purification and characterization. Journal of Biochemistry and Molecular Biology, vol. 39, no. 1, pp. 105-110. PMid:16475280.

- SMITH, D.C. and WOOD, T.M., 1991. Xylanase production by Aspergillus awamorri Development of a medium and optimisation of extracellular xylanase and β- xylosidases while maintaining low protease production. Biotechnology and Bioengineering, vol. 38, no. 8, pp. 883-890. http://dx.doi.org/10.1002/bit.260380810 PMid:18600845.

» http://dx.doi.org/10.1002/bit.260380810 - THOMAS, L., USHASREE, M.V. and PANDEY, A., 2014. An alkali-thermostable xylanase from Bacillus pumilus functionally expressed in Kluyveromyces lactis and evaluation of its deinking efficiency. Bioresource Technology, vol. 165, pp. 309-313. http://dx.doi.org/10.1016/j.biortech.2014.03.037 PMid:24709528.

» http://dx.doi.org/10.1016/j.biortech.2014.03.037 - XUE, H., ZHOU, J., YOU, C., HUANG, Q. and LU, H., 2012. Amino acid substitutions in the N-terminus, cord and α-helix domain improved the thermostability of a family 11 xylanase XynR8. Journal of Industrial Microbiology & Biotechnology, vol. 39, no. 9, pp. 1279-1288. http://dx.doi.org/10.1007/s10295-012-1140-y PMid:22584821.

» http://dx.doi.org/10.1007/s10295-012-1140-y - YANG, V.W., ZHUANG, Z., ELEGIR, G. and JEFFRIES, T.W., 1995. Alkaline active xylanase produced by an alkallophilic Bacillus sp. isolated from kraft pulp. Journal of Industrial Microbiology & Biotechnology, vol. 15, no. 5, pp. 434-441. http://dx.doi.org/10.1007/BF01569971

» http://dx.doi.org/10.1007/BF01569971

Publication Dates

-

Publication in this collection

06 Aug 2021 -

Date of issue

2023

History

-

Received

23 Sept 2020 -

Accepted

01 Mar 2021