Abstract

The aim of this study was to increase rhamnolipid production by formulating media using kefir and fish meal for Pseudomonas aeruginosa strains isolated from different environmental resources. The strains, named as H1, SY1, and ST1, capable of rhamnolipid production were isolated from soil contaminated with wastes originating from olive and fish oil factories. Additionally, P. aeruginosa ATCC 9027 strain, which is known as rhamnolipid producer, was included in the study. Initially, rhamnolipid production by the strains was determined in Mineral Salt Medium (MSM) and then in media prepared by using kefir and fish meal. The obtained rhamnolipids were purified and quantified according to Dubois et al. (1956)Dubois M, Gilles KA, Hamilton JK et al. (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356.. The quantity of rhamnolipids of ATCC, H1 and SY1 strains in kefir media were determined as 11.7 g/L, 10.8 g/L and 3.2 g/L, respectively, and in fish meal media as 12.3 g/L, 9.3 g/L and 10.3 g/L, respectively. In addition, effect of UV light exposure on rhamnolipid production was also investigated but contrary a decrease was observed. The results indicate that P. aeruginosa strains isolated from various environmental resources used in this study can be important due to their rhamnolipid yield, and fish meal, which is obtained from waste of fish, can be an alternative source in low cost rhamnolipid production.

biosurfactant; Pseudomonas aeruginosa ; rhamnolipid; kefir; fish meal

Introduction

Surfactants are surface active agents that can reduce surface and interfacial tensions between two liquids. Biosurfactants are of biological origin and commonly produced by microorganisms (Cooper and Zajic, 1980Cooper DG, Zajic JE (1980) Surface-active compounds from microorganisms. Adv Appl Microbiol 26:229–253.).

Synthetic surfactants cause environmental problems due to their toxicity and are resistant to biodegradation in ecosystem. There is a recent increase in interest for the production of biosurfactants due to their biodegradability, reduced toxicity, selectivity and specific activity at extreme conditions such as temperatures, pH, salinity, etc. (Banat et al., 2000Banat IM, Makkar RS, Cameotra SS (2000) Potential commercial applications of microbial surfactants. Appl Microbiol Biotechnol 53:495–508.; Ron and Rosenberg, 2001Ron EZ, Rosenberg E (2001) Natural roles of biosurfactants. Environ Microbiol 3:229–236.; Nitschke et al., 2011Nitschke M, Costa SGVAO, Contiero J (2011) Rhamnolipids and PHAs: Recent reports on Pseudomonas-derived molecules of increasing industrial interest. Process Biochem 46:621–630.).

Biosurfactants have several applications in petroleum industry, such as microbial enhanced oil recovery, cleaning of oil tankers, and transportation of crude oil. In addition, they have a potential to be used in a variety of industries like cosmetics, pharmaceuticals, food preservatives, and detergents (Desai and Banat, 1997Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential. Microbiol Mol Biol Rev 61:47–64.). In recent years, the studies directed to improve the production has increased to meet growing needs of raw material in many areas where biosurfactants can be used. Rhamnolipid is a biosurfactant produced by Pseudomonas aeruginosa and has a strong potential to be used in industries and bioremediation (Rashedi et al., 2005Rashedi H, Assadi MM, Bonakdarpour B et al. (2005) Environmental importance of rhamnolipid production from molasses as a carbon source. Int J Environ Sci Tech 2:59–62.).

Although interest for biosurfactants is increasing, they are not economically competitive with their synthetic counterparts. High production costs can be accepted only for biosurfactants used in low-volume, and in high priced products such as cosmetics and medicines. Nevertheless, biosurfactants can be produced with high yield by some microorganisms especially Pseudomonas spp. utilizing various renewal resources and industrial wastes. Obtaining maximum yield with a low cost substrate is significantly important in biotechnological processes (Makkar et al., 2011Makkar RS, Cameotra SS, Banat IM (2011) Advances in utilization of renewable substrates for biosurfactant production. ABM Express 1:5. doi:10.1186/2191-0855-1-5.

https://doi.org/10.1186/2191-0855-1-5...

).

Primarily, the amounts of the produced microbial surfactants depend on to the producer organism and factors like carbon and nitrogen sources, trace elements, and production conditions (Patel and Desai, 1997Patel RM, Desai AJ (1997) Biosurfactant production by Pseudomonas aeruginosa GS3 from molasses. Lett Appl Microbiol 25:91–94.). In the literature, there are studies focusing rhamnolipid production using different carbon sources (Soberon-Chavez et al., 2005Soberón-Chávez G, Lépine F, Déziel E (2005) Production of rhamnolipids by Pseudomonas aeruginosa. Appl Microbiol Biotechnol 68:718–725.; Da Silva et al., 2009Da Silva GP, Mack M, Contiero J (2009) Glycerol: A promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39.; Amani et al., 2013Amani H, Muler MM, Syldatk C et al. (2013) Production of microbial rhamnolipid by Pseudomonas aeruginosaMM1011 for ex situ enhanced oil recovery. Appl Biochem Biotechnol 170:1080–1093.; Rikalovic et al., 2013Rikalovic MG, Abdel-Mawgoud AM, Deziel EDjG et al.(2013). Comparative Analysis of Rhamnolipids from Novel Environmental Isolates of Pseudomonas aeruginosa. J Surfact Deterg 16:673–682.; Saikia et al., 2014Saikia RR, Deka H, Goswami D et al. (2014) Achieving the Best Yield in Glycolipid Biosurfactant Preparation by Selecting the Proper Carbon/Nitrogen Ratio. J Surfact Deterg 17:563–571.).

From this point of view, we aimed to isolate highly productive rhamnolipid producer P. aeruginosa strains by taking multiple samples from different regions in Turkey and also tried to increase the rhamnolipid production by these strains by formulating media using kefir and fish meal.

Materials and Methods

Bacterial cultures and identification

P. aeruginosa strains were isolated from water and soil samples from 26 different regions in Turkey. Nine strains were found to produce rhamnolipid. The most efficient rhamnolipid producing three strains (H1, SY1, and ST1) were selected for further studies on the basis of maximum rhamnolipid yield on a media consisting kefir and fish meal. In addition, P. aeruginosa ATCC 9027 was included in this study as a control. P. aeruginosa H1 and SY1 strains were isolated from soil samples contaminated with waste of olive oil factory. P. aeruginosa ST1 strain was isolated from soil sample contaminated with waste of fish oil factory.

In order to isolate microorganisms, 1 g of soil sample was inoculated in the tubes containing 9 mL of nutrient broth. Inoculated tubes were incubated at 37 °C for 24 h. 0.1 mL from enrichment tube was placed on Cetrimide agar and incubated at 37 °C for 24 h. Pigment production in bacteria was examined; and bacteria that produced blue-green or yellow-green pigments were separated for identification with conventional methods (morphologically and biochemically), and API 20NE kits were used for verifying of the results.

Media and culture conditions for rhamnolipid production

The production of rhamnolipid by the strains was determined by using MSM, recommended by Zhang et al.(2005)Zhang G, Wu Y, Qian X et al. (2005) Biodegradation of crude oil by Pseudomonas aeruginosa in the presence of rhamnolipids. J Zhejiang Univ 8:725–730.. The following components (g/L) were used for the growth of the isolates; NaNO3 4.0, NaCl 1.0, KCl 1.0, CaCl2.2H2O 0.1, KH2PO4 3.0, Na2HPO4.12H2O 3.0, MgSO4 2.0, FeSO4.7H2O 0.001. A stock solution of trace elements was composed of (g/L): FeCl3.6H2O 0.08, ZnSO4.7H2O 0.75, CoCl2.6H2O 0.08, CuSO4.5H2O 0.075, MnSO4.H2O 0.75, H3BO3 0.15, Na2MoO4.2H2O 0.05. The initial pH was adjusted to 6.8. The strains were activated twice in nutrient broth, and then bacterial suspensions were adjusted to McFarland 2. Finally, they were inoculated into MSM at the ratio of 1/20. Bacterial cultivation was performed in 500 mL flask containing 200 mL medium at 35 °C, stirred in an orbital rotary shaker (STIR) at 150 rpm for 7 days.

Medium with kefir

The ingredients (%) of the kefir used in the medium were as follows (%): water 88–89, lactic acid 0.8–0.9, ethyl alcohol 0.6–1.1, lactose 1.7–2.7, casein 2.5–2.9, minerals 0.6–0.8, albumin 0.1–0.3, oil 2.8–3.3. Firstly, kefir was filtered with a filter paper, and diluted two-fold by phosphate buffer. This solution was enhanced by 0.5 g NaCl and 1 mL trace element solution, and autoclaved at 121 °C for 15 min. Bacterial suspension was added into this medium and incubated in an orbital rotary shaker (STIR) at 150 rpm for 7 days.

Fish meal medium

Fish meal used in medium was obtained from a fish oil factory in Turkey. The composition of the fish meal used in the medium was as follows (%): crude material 91.7, moisture 8.3, crude protein 65.3, crude fat 8.9, crude ash 14.2, glycine 5.09, histidine 2.0, isoleucine 3.33, leucine 5.48, lysine 5.69, methionine 2.19, phenylalanine 3.15, threonine 3.30, tyrosine 2.38, and valine 4.04. The medium was prepared by adding three-fold water and keeping it at 4 °C for overnight. Next day, it was filtered, and filtrate was enhanced by adding 0.5 g NaCl and 1 mL trace element solution and then autoclaved at 121 °C for 15 min.

Purification of rhamnolipid

After 7 days of incubation period, pH was adjusted to 8.0 (using 10 M NaOH), and biomass was removed by centrifugation for 20 min at 9,000 × g. The pH of supernatant was adjusted to 2 (using 6 M H2SO4), and it was kept overnight at 4 °C. Next day equal volume of chloroform-methanol (2:1) mixture was added. The resultant suspension was shaken for 10 min in rotary shaker and organic phase was removed. The extraction process was repeated one more time. The obtained rhamnolipid was concentrated from pooled organic phases by using a rotary evaporator (Heidolph, Laborota 4000), the product was dissolved in analytical grade methanol and filtered (Sterivex-GV, 0.22 mm; Millipore, Bedford, MA, USA) for spectrophotometric analysis (Mata-Sandoval et al., 1999Mata-Sandoval JC, Karns J, Torrents A (1999) High-performance liquid chromatography method for the characterization of rhamnolipid mixtures produced by Pseudomonas aeruginosa UG2 on corn oil. J Chromatogr A 864:211–220.).

Characterization of rhamnolipid

Thin layer chromatography (TLC)

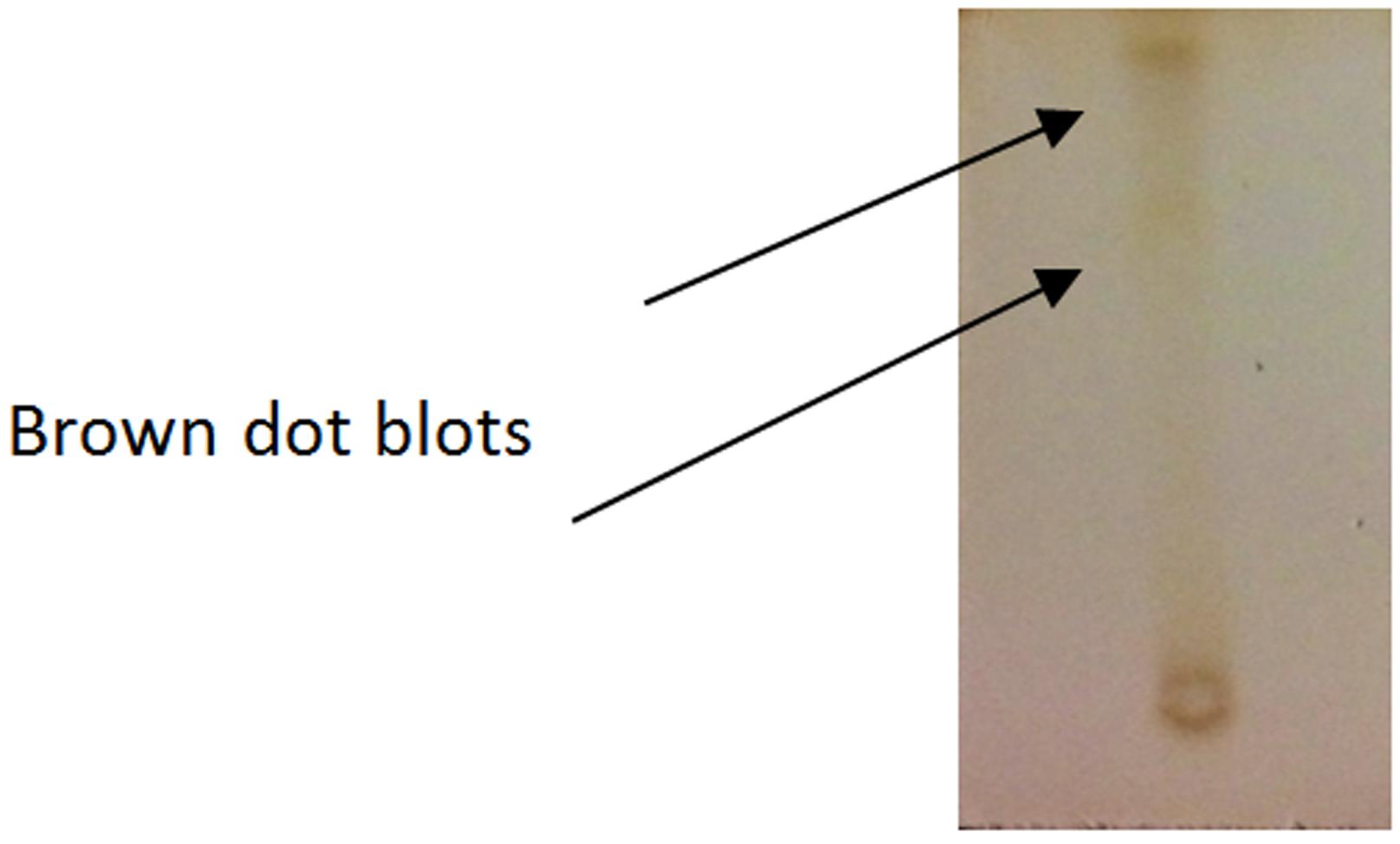

The extracted rhamnolipids were dissolved in chloroform-methanol (9:1). 2 μL of the sample was applied onto TLC plates (Merck) with chloroform: methanol: acetic acid (65:15:2) solution as the developing solvent. The TLC plates were dipped in 15% H2SO4 in ethanol and incubated at 100 °C. Appearance of brown dot was considered as presence of glycolipids.

UV spectrophotometric analysis

Rhamnolipid concentration was determined according to Dubois et al. (1956)Dubois M, Gilles KA, Hamilton JK et al. (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. by the colorimetric phenol-sulfuric acid method at 480 nm by using a Shimadzu 1601 PC double beam spectrophotometer equipped with 1.0 cm quartz cells with a fixed slit width (2 nm). Stock solutions of 1 mg/mL of the L-rhamnose was prepared in bidistilled water. Standard solutions were prepared by serial dilution to contain the concentration required for the calibration curves. The rhamnolipid concentration was calculated from a standard curve prepared with L-rhamnose (Difco, USA). The measurements were carried out by additing 5 mL of concentrated sulfuric acid and 50 μL of 80% phenol into these solutions prepared. Calibration curve was formed with obtained absorbance values and used for determination of rhamnolipid amounts. Purified product obtained after evaporation was dissolved in methanol and filtered with 0.22 μm Millipore filter to quantify rhamnolipid. 2 mL of the sample, 50 μL of 80% phenol, 2.95 mL distilled water and 5 mL H2SO4 was added slowly, after cooling, OD was taken using a UV spectrophotometer at 480 nm.

Effects of different parameters on rhamnolipid production

UV light effects on rhamnolipid production

In order to investigate UV light effects on rhamnolipid production, inoculum suspension of P. aeruginosa ATCC 9027 strain was prepared according to McFarland 2 density. 20 μL of this suspension was added and spread on Mueller Hinton Agar (Merck, Germany) medium in Petri dishes, and then was exposed to UV rays for 60, 75, 90, 105 and 120 s. The source of UV radiation was fluorescent lights (Philips, 20 W/C) with an emission spectrum of 250–370 nm and a peak at 254 nm. The distance between the lamp and applied surfaces was 30 cm in all tests. After UV exposure for the desired duration, all samples were incubated at 37 °C until microbial growth was seen in positive control medium. The Petri dishes were examined after incubation. Bacterial suspensions were prepared according to McFarland 2, from colonies obtained from these Petri dishes after UV light exposure. These suspensions were added (ratio of 1/20) to MSM and incubated at 150 rpm for 7 days. At the end of the incubation, rhamnolipid concentrations were determined.

Consecutive incubation effects on rhamnolipid production

In order to investigate the effects of consecutive incubation, P. aeruginosa ATCC 9027 strain was incubated in MSM for 7 days, then transferred into nutrient broth and incubated overnight. Next day, bacterial suspension was prepared from fresh culture, added into MSM and incubated for 7 days. The process was repeated 4 times. After each incubation period, the amount of rhamnolipid was determined.

Statistical analyses

Results were average of at least three independent measurements. Statistical significance was assessed by one way ANOVA using SPSS for Windows (Version 17.0) packet program. The level of significance was defined at p < 0.05.

Results

Bacteria that produced blue-green or yellow-green pigment in cetrimide agar were identified according to Bergey’s Manual of Systematic Bacteriology based on the morphological, and biochemical characteristic. API 20NE kits were used for verification of results.

Nine isolates were determined as rhamnolipid producer. Additionally P. aeruginosa ATCC 9027 which has been known as rhamnolipid producer was also included.

The TLC results are shown in Figure 1. All strains produced spots on TLC plates, indicating that strains could produce glycolipids.

Initially rhamnolipid production was observed in MSM. The obtained rhamnolipid concentrations are given in Table 1.

Three strains (H1, ST1, and SY1) with the maximum yield and ATCC 9027 were selected for further studies. The rhamnolipid concentrations in media and increased rhamnolipid yield in kefir and fish meal are given in Table 2 and 3.

The obtained rhamnolipid concentrations at 60, 75, 105, 115, and 120 s after exposure to UV rays were 1680, 1661, 1337, 1403, 1370 mg/mL, respectively.

The results showed no increase in rhamnolipid concentrations by exposing P. aeruginosa ATCC 9027 to UV rays; contrary, a decrease in concentration was observed depending on the increasing time. No change was observed in rhamnolipid concentrations in P. aeruginosa ATCC 9027 strain when exposed UV rays sequentially during the incubation period.

Discussion

The success of biosurfactant production depends on producer microorganisms, development process, and raw materials. In this study, our first aim was to isolate Pseudomonas aeruginosa strains with high rhamnolipid yields. For this purpose, water and soil samples were collected from 26 different places in Turkey. It is known that P. aeruginosa strains produce better rhamnolipid in oily environments; therefore, we preferred samples from oily areas contaminated with factory wastes. Our results established that the isolated strains have good rhamnolipid yield compared to those reported elsewhere, in terms of the amounts, we achieved in MSM (Rashedi et al., 2005Rashedi H, Assadi MM, Bonakdarpour B et al. (2005) Environmental importance of rhamnolipid production from molasses as a carbon source. Int J Environ Sci Tech 2:59–62.; George Jayachandran, 2012George S, Jayachandran K (2012) Production and characterization of rhamnolipid biosurfactant from waste frying coconut oil using a novel Pseudomonas aeruginosa D. J Appl Microbiol 114:373–383.).

The quality and quantity of biosurfactant are influenced by carbon and nitrogen substrates, the concentration of elements in medium, culture conditions, such as pH, temperature, and agitation, dilution rate in culture in addition to the microorganisms. In this study, the optimum culture conditions were determined as pH 6.8, temperature 35 °C, agitation rate 150 rpm, and incubation time 7 days, considering previous studies about biosurfactant production by P. aeruginosa (Chen et al., 2007Chen SY, Wei YH, Chang JS (2007) Repeated pH-stat fed-batch fermentation for rhamnolipid production with indigenous Pseudomonas aeruginosa S2. Appl Microbiol Biotechnol 76:67–74.; Panesar et al., 2011Panesar R, Panesar PS, Bera MB (2011) Development of low cost medium for the production of biosurfactants. Asian Journal of Biotechnology doi: 10.3923/ajbkr.

https://doi.org/10.3923/ajbkr...

; Sahoo et al., 2011Sahoo S, Datta S, Biswas D (2011) Optimization of culture condition for biosurfactant from Pseudomonas aeruginosa OCD1. JASR 2:32–36.; George and Jayachndran, 2012George S, Jayachandran K (2012) Production and characterization of rhamnolipid biosurfactant from waste frying coconut oil using a novel Pseudomonas aeruginosa D. J Appl Microbiol 114:373–383.).

In present study, kefir, which is a fermented milk drink containing lactose, casein, albumin, fat and good amounts of elements like calcium, magnesium, phosphorus, fluorine and selenium, was used to increase the production of rhamnolipids. In literature survey, addition of magnesium, calcium, potassium, sodium salts and trace elements to media has been reported to improve rhamnolipid production in P. aeruginosa. Kefir was used in this work due to its rich contents. The amount of rhamnolipids in ATCC, H1 and SY1 strains were determined as 11.7, 10.8, 3.2 g/L, respectively, in kefir medium. Especially the yields in ATCC (p = 0.003) and ST1 (p = 0.000) strains in kefir were statistically higher than compared to those in MSM. To the best of our knowledge, there is no study related with use of kefir in rhamnolipid production; however, whey which has high protein, lactose and fat content similar to kefir, has been used (Dubey and Juwarkar, 2004Dubey K, Juwarkar A (2004) Determination of genetic basis for biosurfactant production by Pseudomonas aeruginosa strain BS2. Indian J Biotechnol 3:74–81.). This study was conducted on P. aeruginosa BS2 strain and the obtained rhamnolipid amount was 0.92 g/L. In another study from Turkey, Kahyaoglu and Konar (2008)Kahyaoglu M, Konar V (2008) Karbon kaynagi olarak peyniralti suyu atigi Kullanilarak ramnolipit biyosürfektani üretimi. Afyon Kocatepe Üniversitesi Fen Bilimleri Dergisi 8:53–62. reported 0.48 g/L rhamnolipid with P. aeruginosaDSM 50071 strain. Rhamnolipid quantities obtained in the mentioned studies were not compared those could have been obtained in a basic medium like MSM. The main point, in these studies, was that whey can be used for rhamnolipid production. The results, obtained from above studies using two different strains are compared in the present work, the amounts of rhamnolipids are much higher than those produced in medium consisting kefir filtrate. Kefir is more expensive than whey, however, high production costs can be accepted for biosurfactants used in low-volume and high priced products such as cosmetics and pharmaceuticals (Makkar and Cameotra, 2002Makkar RS, Cameotra SS (2002) An update on the use of unconventional substrates for biosurfactant production and their new applications. Appl Microbiol Biotechnol 58:428–434.).

The other raw material used to increase rhamnolipid production is fish meal, which is produced from fish and bones and offal of processed fish. Fish meal is known for its high protein and mineral content, which make it useful as animal feed additive. In our study, the obtained rhamnolipid amounts were 12.3, 10.3 and 9.3 g/L with ATCC, SY1 and ST1 strains, respectively, in fish meal medium. All values were found statistically significant in fish meal and p-values were 0.002, 0.001 and 0.000 for ATCC, SY1 and ST1 strains, respectively.

In literature survey, we found no study using fish meal, but found two using fish oil. Lee et al. (2004)Lee K, Hwang SH, Ha S et al. (2004) Rhamnolipid production in batch and fed-batch fermentation using Pseudomonas aeruginosa BYK-2 KCTC 18012P. Biotechnol Biopro Eng 9:267–273., while studying P. aeruginosa BYK-2 KCTC 18012P strain, used fish oil (25 g/L) as carbon source. Different from the present work, they also used fed-batch fermentation method and achieved 17 g/L rhamnolipid. On the other hand, Prieto et al. (2008)Prieto LM, Michelon M, Burkert JFM et al. (2008) The production of rhamnolipid by a Pseudomonas aeruginosastrain isolated from a southern coastal zone in Brazil. Chemosphere 71:1781–1785.used soybean- and fish oil in their study. They added 40 g/L of each oil in the basal medium and reported 0.94 g/L rhamnose production in soybean oil but noted less amount of rhamnose in fish oil.

In the present work, rhamnolipid amounts for all the three strains were found statistically higher in fish meal medium compared to MSM. The results showed that fish meal can be a suitable source because of its high yield and lower cost.

In addition, two more parameters, exposure to UV radiation and successive incubation, to enhance rhamnolipid production were also investigated. After culturing from colonies, there was no difference between rhamnolipid amounts obtained from strain exposed to UV radiation and the unexposed control. ATCC 9027 strain was incubated for four periods, each of 7 days, and rhamnolipid quantities were determined at each period. There was no statistically significant difference between the amounts of rhamnolipids obtained after each period.

In conclusion, considering the rhamnolipid amounts, obtained in the modified media, kefir and fish meal can be considered as important additives to increase rhamnolipid yield. Especially, fish meal, for being produced from unprocessed fish waste and low cost, can be a more suitable source for rhamnolipid production.

References

- Amani H, Muler MM, Syldatk C et al. (2013) Production of microbial rhamnolipid by Pseudomonas aeruginosaMM1011 for ex situ enhanced oil recovery. Appl Biochem Biotechnol 170:1080–1093.

- Banat IM, Makkar RS, Cameotra SS (2000) Potential commercial applications of microbial surfactants. Appl Microbiol Biotechnol 53:495–508.

- Chen SY, Wei YH, Chang JS (2007) Repeated pH-stat fed-batch fermentation for rhamnolipid production with indigenous Pseudomonas aeruginosa S2. Appl Microbiol Biotechnol 76:67–74.

- Cooper DG, Zajic JE (1980) Surface-active compounds from microorganisms. Adv Appl Microbiol 26:229–253.

- Da Silva GP, Mack M, Contiero J (2009) Glycerol: A promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39.

- Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential. Microbiol Mol Biol Rev 61:47–64.

- Dubey K, Juwarkar A (2004) Determination of genetic basis for biosurfactant production by Pseudomonas aeruginosa strain BS2. Indian J Biotechnol 3:74–81.

- Dubois M, Gilles KA, Hamilton JK et al. (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356.

- George S, Jayachandran K (2012) Production and characterization of rhamnolipid biosurfactant from waste frying coconut oil using a novel Pseudomonas aeruginosa D. J Appl Microbiol 114:373–383.

- Kahyaoglu M, Konar V (2008) Karbon kaynagi olarak peyniralti suyu atigi Kullanilarak ramnolipit biyosürfektani üretimi. Afyon Kocatepe Üniversitesi Fen Bilimleri Dergisi 8:53–62.

- Lee K, Hwang SH, Ha S et al. (2004) Rhamnolipid production in batch and fed-batch fermentation using Pseudomonas aeruginosa BYK-2 KCTC 18012P. Biotechnol Biopro Eng 9:267–273.

- Makkar RS, Cameotra SS (2002) An update on the use of unconventional substrates for biosurfactant production and their new applications. Appl Microbiol Biotechnol 58:428–434.

- Makkar RS, Cameotra SS, Banat IM (2011) Advances in utilization of renewable substrates for biosurfactant production. ABM Express 1:5. doi:10.1186/2191-0855-1-5.

» https://doi.org/10.1186/2191-0855-1-5 - Mata-Sandoval JC, Karns J, Torrents A (1999) High-performance liquid chromatography method for the characterization of rhamnolipid mixtures produced by Pseudomonas aeruginosa UG2 on corn oil. J Chromatogr A 864:211–220.

- Nitschke M, Costa SGVAO, Contiero J (2011) Rhamnolipids and PHAs: Recent reports on Pseudomonas-derived molecules of increasing industrial interest. Process Biochem 46:621–630.

- Panesar R, Panesar PS, Bera MB (2011) Development of low cost medium for the production of biosurfactants. Asian Journal of Biotechnology doi: 10.3923/ajbkr.

» https://doi.org/10.3923/ajbkr - Patel RM, Desai AJ (1997) Biosurfactant production by Pseudomonas aeruginosa GS3 from molasses. Lett Appl Microbiol 25:91–94.

- Prieto LM, Michelon M, Burkert JFM et al. (2008) The production of rhamnolipid by a Pseudomonas aeruginosastrain isolated from a southern coastal zone in Brazil. Chemosphere 71:1781–1785.

- Rashedi H, Assadi MM, Bonakdarpour B et al. (2005) Environmental importance of rhamnolipid production from molasses as a carbon source. Int J Environ Sci Tech 2:59–62.

- Rikalovic MG, Abdel-Mawgoud AM, Deziel EDjG et al.(2013). Comparative Analysis of Rhamnolipids from Novel Environmental Isolates of Pseudomonas aeruginosa J Surfact Deterg 16:673–682.

- Ron EZ, Rosenberg E (2001) Natural roles of biosurfactants. Environ Microbiol 3:229–236.

- Sahoo S, Datta S, Biswas D (2011) Optimization of culture condition for biosurfactant from Pseudomonas aeruginosa OCD1. JASR 2:32–36.

- Saikia RR, Deka H, Goswami D et al. (2014) Achieving the Best Yield in Glycolipid Biosurfactant Preparation by Selecting the Proper Carbon/Nitrogen Ratio. J Surfact Deterg 17:563–571.

- Soberón-Chávez G, Lépine F, Déziel E (2005) Production of rhamnolipids by Pseudomonas aeruginosa Appl Microbiol Biotechnol 68:718–725.

- Zhang G, Wu Y, Qian X et al. (2005) Biodegradation of crude oil by Pseudomonas aeruginosa in the presence of rhamnolipids. J Zhejiang Univ 8:725–730.

Publication Dates

-

Publication in this collection

Jul-Sep 2015

History

-

Received

26 Aug 2014 -

Accepted

02 Feb 2015