Abstract

In order to overproduce bioinsecticides production by a sporeless Bacillus thuringiensis strain, an optimal composition of a cheap medium was defined using a response surface methodology. In a first step, a Plackett-Burman design used to evaluate the effects of eight medium components on delta-endotoxin production showed that starch, soya bean and sodium chloride exhibited significant effects on bioinsecticides production. In a second step, these parameters were selected for further optimisation by central composite design. The obtained results revealed that the optimum culture medium for delta-endotoxin production consists of 30 g L-1 starch, 30 g L-1 soya bean and 9g L-1 sodium chloride. When compared to the basal production medium, an improvement in delta-endotoxin production up to 50% was noted. Moreover, relative toxin yield of sporeless Bacillus thuringiensis S22 was improved markedly by using optimised cheap medium (148.5 mg delta-endotoxins per g starch) when compared to the yield obtained in the basal medium (94.46 mg delta-endotoxins per g starch). Therefore, the use of optimised culture cheap medium appeared to be a good alternative for a low cost production of sporeless Bacillus thuringiensis bioinsecticides at industrial scale which is of great importance in practical point of view.

sporeless Bacillus thuringiensis; delta-endotoxins; cheap medium; optimisation; response surface methodology

INDUSTRIAL MICROBIOLOGY

RESEARCH PAPER

Application of statistical experimental design for optimisation of bioinsecticides production by sporeless Bacillus thuringiensis strain on cheap medium

Saoussen Ben KhedherI; Samir JaouaI,II; Nabil ZouariI,II

ITeam of Biopesticides, Centre of Biotechnology of Sfax, University of Sfax, Sfax, Tunisia

IIBiological and Environmental Sciences Department, College of Arts and Sciences, Qatar University, Doha, Qatar

Correspondence Correspondence N. Zouari Team of Biopesticides Centre of Biotechnology of Sfax University of Sfax P.O. Box 1177, 3018 Sfax, Tunisia E-mail: nabil.zouari@cbs.rnrt.tn

ABSTRACT

In order to overproduce bioinsecticides production by a sporeless Bacillus thuringiensis strain, an optimal composition of a cheap medium was defined using a response surface methodology. In a first step, a Plackett-Burman design used to evaluate the effects of eight medium components on delta-endotoxin production showed that starch, soya bean and sodium chloride exhibited significant effects on bioinsecticides production. In a second step, these parameters were selected for further optimisation by central composite design. The obtained results revealed that the optimum culture medium for delta-endotoxin production consists of 30 g L-1 starch, 30 g L-1 soya bean and 9g L-1 sodium chloride. When compared to the basal production medium, an improvement in delta-endotoxin production up to 50% was noted. Moreover, relative toxin yield of sporeless Bacillus thuringiensis S22 was improved markedly by using optimised cheap medium (148.5 mg delta-endotoxins per g starch) when compared to the yield obtained in the basal medium (94.46 mg delta-endotoxins per g starch). Therefore, the use of optimised culture cheap medium appeared to be a good alternative for a low cost production of sporeless Bacillus thuringiensis bioinsecticides at industrial scale which is of great importance in practical point of view.

Key words: sporeless Bacillus thuringiensis, delta-endotoxins, cheap medium, optimisation, response surface methodology.

Introduction

During the last decades, the efficiency of Bacillus thuringiensis (B. thuringiensis) in pest management has extended its use in agriculture, forestry and urban sectors (Navon, 2000). The larvicidal activity of these bioinsecticides is based on parasporal crystals produced by the bacterial cells during the sporulation phase (Aronson, 1993). In order to enhance the efficiency of B. thuringiensis, overproducing sporeless mutants have been isolated by random mutagenesis (Ben Khedher et al., 2011b). These sporeless strains are more environmentally friendly and have many advantages such as a high delta-endotoxin production, a protection of encapsulated crystal from the harmful effect of UV-radiations and no viable spores would be present in their formulated products. For achieving an industrial production on a large scale of such bioinscticides, it is necessary to improve the production process, especially by designing a suitable culture medium. The use of low cost carbon and nitrogen sources is an attractive alternative because of the ability of B. thuringiensis to use complex substrates (Kanekar et al., 2002). Several locally available cheap materials such as gruel, fish meal (Zouari et al., 1998), corn steep liquor, coconut waste, rice bran and molasses were reported for B. thuringiensis production (Saalma et al., 1983; Desai and Shethna, 1991; Lee and Seleena, 1991; Kumar et al., 2000). In order to improve deltaendotoxin production by sporeless B. thuringiensis, commercial grades of starch and soya bean were used as carbon and nitrogen sources respectively, for medium optimisation. Since, in a previous reported work (Ben Khedher et al., 2011b) overproducing sporeless (asporogenic and oligosporogenic) mutants were shown to overproduce delta-endotoxins compared to sporulating wild strain, an asporogenic B. thuringiensis strain S22 was used in this work. In the present study, a Plackett-Burman design was carried out to screen the cultural parameters that may affect delta-endotoxin production, followed by a central composite design (CCD) involved in the optimisation of significant ones, needed towards the optimal production of delta-endotoxin by sporeless B. thuringiensis, in a low cost medium.

Materials and Methods

Strain

The sporeless B. thuringiensis subsp kurstaki strain S22 is used as a representative strain for the study (Ben Khedher et al., 2011b).

Inocula preparation

The inocula were prepared as reported by Ghribi et al. (2004). The culture broth was used to inoculate the studied media to start with an initial cell density of 1.95 x 107 cfu mL-1.

Culture medium

Commercial grade starch was kindly provided from a local agro-industry (G.I.A. Slama, Bouargoug, Tunisia). Commercial soya bean, containing 46% proteins, was obtained from a local mill of animal meals (ALCO Affes Group, Sfax, Tunisia). The modified complex medium (NaCl was added) previously described by Ghribi et al. (2007) was used with the following composition (g L-1): starch, 30; soya bean, 25; KH2PO4, 1; K2HPO4, 1; MgSO4, 0.3; MnSO4, 0.01 and FeSO4, 0.01. Medium pH was adjusted to 7.0 before sterilization at 121 °C for 20 min. In 250 mL flask, 0.4 g of CaCO3 was added for maintaining of pH stability. The 250 mL flask containing 20 mL of culture medium was incubated for 96 h at 30 °C in a rotary shaker set at 200 rev min-1.

Screening of important medium components

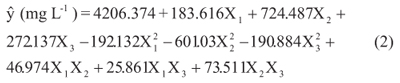

A Plackett-Burman design with 12 experiments was carried out for screening the effect of eight potential parameters. Each row of the matrix represented a trial and each column represented an independent factor whose levels were varied. Each variable was evaluated at two levels, a high (1) and a low (-1) level (Table 1). The levels attributed to each variable were determined based on results of preliminary study (data not shown). For the present study, the selected variables included starch, soya bean, NaCl, KH2PO4, K2HPO4, MgSO4, MnSO4 and FeSO4.

Optimisation of significant variables by a CCD

A CCD for the three selected variables (starch, soya bean and NaCl) was carried out in order to optimise deltaendotoxin production and to determine the optimum levels of the investigated parameters. Each variable was analysed at five levels coded as -α,-1, 0, +1 and +α (Table 2). The second order model associated to the three variables CCD is:

In the above equation, η is the theoretical response model, β0, β1, ..., β12 represent the model coefficients and Xj (j=1 to 3) are the coded parameters selected for the CCD. The NemrodW software (Mathieu et al., 2000) was used for experimental design and data analysis.

Delta-endotoxin determination

Delta-endotoxin concentration was determined in the solubilised crystal preparation from each culture medium as described by Zouari et al. (1998). The values presented are the average of two separate experiments for each cultural condition.

Results and Discussion

Screening of medium parameters affecting delta-endotoxin production

The objective of Plackett-Burman design (Table 3) was to screen, among eight independent variables, the factors with main effects on toxin production of a sporeless B. thuringiensis strain S22 (Myers and Montgomery, 1995; Khuri and Cornell, 1996). The importance of eight medium components, namely, starch, soya bean, K2HPO4, KH2PO4, NaCl, MgSO4, FeSO4 and MnSO4 for delta-endotoxin production is shown in Table 4. Results of Table 4 illustrated the statistical significance of the model coefficients, determined by Student's t-test. Starch, soya bean and NaCl appeared to be the major variables that positively affected delta-endotoxin production. Our results agree with reports that both carbon and nitrogen sources are the main components that affect the synthesis rate of delta-endotoxins (Farrera et al., 1998). Moreover, our findings confirmed that adaptation of B. thuringiensis cells to NaCl was beneficial in cheap complex production media (Ghribi et al., 2005). The other components were considered as least important factors. However, Tokcaer et al. (2006) reported that K2HPO4 and MnSO4 levels were critical for effective synthesis of crystal toxin specifically favoured biosynthesis. Nevertheless, according to the coefficient estimate analysis (Table 4), KH2PO4, K2HPO4, MgSO4, MnSO4 and FeSO4 have no significant effect on delta-endotoxin synthesis, although the yield of toxin production is known to be greatly influenced by trace metals and other minerals.

Therefore, the three most significant components (starch, soya bean and NaCl) were selected for further optimisation by response surface analysis.

Response surface analysis

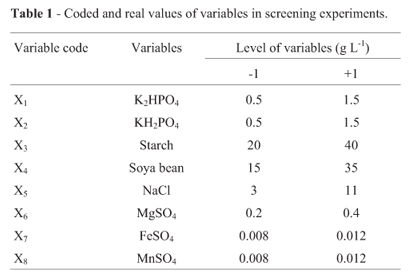

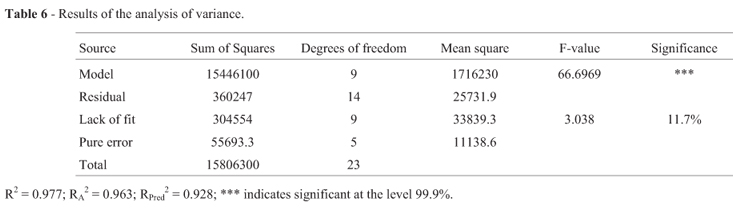

On the basis of our findings, starch, soya bean and NaCl, the most influenced factors in low cost medium (Table 2), were optimised using a CCD design. In this regard, a set of 24 experiments including, six center points and four check-points, (runs numbers 21 to 24) in order to check the validity of the fitted model, were carried out. The experimental and predicted responses for delta-endotoxin production are reported in Table 5. All experiments were carried out in duplicate. A multiple regression analysis of the data was carried out with the statistical analysis (Table 6). According to Table 6, the regression effect was statistically highly significant [(P > F) < 0.01] at 97.7% of confidence level. The model also showed insignificant lack of fit [(P > F) = 11.7]. The fit of the model was also expressed by the coefficient of regression R2, which was found to be 0.977, indicating that 97.7% of the variability in the response (delta-endooxin production) could be explained by the model. Other parameters of ANOVA for response surface quadratic model were also studied. The RPred2 of 0.928 is in reasonable agreement with the RA2 of 0.963. These results reinforced that the response equation provided a suitable model for the CCD experiment.

Therefore, the model was probably adequate for prediction within the range of variables employed. The model can be shown as follows:

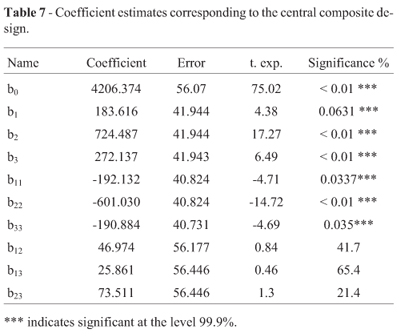

where y is the response that is delta-endotoxin production, X1, X2 and X3 are the coded values of starch, soya bean and NaCl concentrations, respectively. The significance of the regression coefficients was tested by the Student's t-test. The regression coefficients and corresponding p-values for the model are presented in Table 7. The p-values were used as a tool to check the significance of each coefficient, which was necessary to understand the pattern of the mutual inter-actions between the three variables. Values of P less than 0.05 indicate model terms are significant. The results showed that the independent factors, starch (X1), soya bean (X2), NaCl (X3) and their quadratic terms (X12, X22 and X32) have significant effects on delta-endotoxin production.

However, their interaction effects are found to be insignificant (Table 7).

The coded model was used to generate three-dimensional response surface curves presentations to understand the interaction of medium components and to determine the optimal concentration of each one conducting to the maximal delta-endotoxin production (Figure 1a-c).

Figure 1a illustrated the effect of starch (14-45 g L-1) and soya bean (9-41 g L-1) concentrations on delta-endotoxin production at7g L-1 NaCl. Starch concentration (X1) has no significant effect on the considered response in the presence of 15-25 g L-1 soya bean. A positive effect of starch is noticed in the presence of a concentration of soya bean higher than 25 g L-1. Indeed, the surface curves showed that a high delta-endotoxin production (4470 mg L-1) can be reached when using high concentrations of both starch and soya bean (over 30 g L-1). However, delta-endotoxin production declined sharply thereafter, by increasing both starch and soya bean concentrations over 35 g L-1. In fact, increasing starch concentration beyond 35 g L-1 led to a decline of delta-endotoxin production yield. This might be explained by the fact that toxin production is subject to catabolite repression which could be exhibited at high starch concentration (over 35 g L-1). This metabolic limitation was previously described (Zouari et al., 1998, 2002a) when using glucose or gruel as carbon sources (Zouari et al., 2002b) in delta-endotoxin production. But, this effect seems to be less exhibited with starch. Consequently, the results of this study revealed that starch, known to have a repressive and/or inhibitory effect on toxin synthesis (Özkan et al., 2003), supported a good delta-endotoxin production, since B. thuringiensis S22 strain has been shown to produce protease in substantially high yields (data not shown). So, this carbon source, used as low-cost and available substrate at an industrial scale, is readily used. This finding is promising since Içgen et al. (2002) reported that the use of maltose, starch and dextrin did not improve B. thuringiensis crystal titers. On the other hand, they also demonstrated that soya bean was among the best nitrogenous substrates which supported an optimal toxin production (Içgen et al., 2002), which agree with our findings.

When using more than 35 g L-1 soya bean, a decrease in delta-endotoxin production was noticed, which could be attributed to a high biomass production as that could be expected (Zouari and Jaoua, 1999; Prabakaran and Balaraman, 2006) and therefore affected crystal production. On the other hand, this decrease of toxin production could be due to the repression or inhibition of secondary metabolism by nitrogen sources. In fact, the nitrogen catabolite regulation has been frequently reported and well illustrated (Demain, 1995).

Therefore, delta-endotoxin production heavily depends on the availability of both carbon and nitrogen sources in the medium. Both exhibited regulatory effects on toxin synthesis. So, when using starch and soya bean at adequate concentrations, an overproduction of delta-endotoxins could be achieved. As shown in Figure 1b, delta-endotoxin production was enhanced especially by increasing starch concentration and using moderate NaCl concentration (9 g L-1), at soya bean concentration of 25 g L-1. This result suggested that NaCl supply led to an improvement of delta-endotoxin production (Ghribi et al., 2005; Ben Khedher et al., 2011a), particularly when used at 9g L-1 and declined thereafter. In fact, NaCl addition plays the role of inducer of cell growth and consequently of delta-endotoxin production by sporeless B. thuringiensis mutants (Ben Khedher et al., 2011a). It also could involve the synthesis of osmoprotectants, solutes, and/or amino acids which are known to protect cellular constituents in bacteria (Ruzal et al., 1994). However, NaCl concentration over than 10 g L-1 can reduce the operational stability of the cells and affect its capacity to grow and produce crystal proteins (Amezega et al., 1995). Figure 1c showed the effect of varying soya bean concentration from 8 to 42 g L-1 and NaCl concentration from 0.3 to 11 g L-1 on delta-endotoxin production at a starch concentration of 30 g L-1. A positive effect of NaCl concentration is clear in the presence of high concentrations of soya bean (beyond 25 g L-1).

In this attempt, a careful balance of substrates which are convenient and attractive because they are inexpensive must be provided to achieve an optimal delta-endotoxin production. Indeed, the surface curves showed that high delta-endotoxin production (4432 mg.L-1) was achieved by using 30g L-1 soya bean and 9 g.L-1 NaCl. Consequently, under the following conditions, 30 g.L-1 starch, 30 g L-1 soya bean and 9g L-1 NaCl, a maximal delta-endotoxin production was predicted by the model, at of 4432 ± 56.2 mg L-1.

Confirmation

In order to validate the predicted results, S22 strain was cultivated using optimised medium, in duplicate. The results clearly showed that the experimental response values (4455 mg L-1) agree with those calculated (4432 ± 56.2 mg L-1). Once again, this verification revealed a high degree of accuracy of the model under the investigated conditions. When compared to basal medium production (2834 mg L-1), we noted an improvement of delta-endotoxin production reaching 57%, after optimisation of cheap medium composition. This toxin production improvement was also associated to yields improvement, calculated as the ratio of delta-endotoxin (mg L-1) over assimilated starch (g L-1), which reached 148.5 mg g-1 of starch in optimised medium, compared to 94.46 mg g-1 of starch in basal medium. Zouari et al. (2002b) reported that BNS3 toxin production was 3194 mg L-1 when used 42 g L-1 gruel and 20 g L-1 fish meal. Interestingly, delta-endotoxin production of S22 in our optimised medium exhibited 39.48% toxin production improvement, comparatively to BNS3 toxin production. So, considering the high production and stability of bioinsecticides based on sporeless B. thuringiensis, S22 strain is a promising strain for biotechnological applications, especially when used our optimised cheap medium.

Acknowledgments

This work was supported by grants from the Tunisian Ministry of Higher Education and Scientific Research.

Submitted: October 04, 2011;

Approved: November 13, 2012.

All the content of the journal, except where otherwise noted, is licensed under a Creative Commons License CC BY-NC.

- Amezega MR, Davidson I, McLaggan D, Verheyul A, Abee T, Booth I (1995) The role of peptide metabolism in the growth of Listeria monocytogenes ATCC 23074 at high osmolarity. Microbiology 141:41-49.

- Aronson AI (1993) The two faces of Bacillus thuringiensis: insecticidal proteins and post exponential survival. Mol Microbiol 7:489-96.

- Ben Khedher S, Jaoua S, Zouari N (2011a) Improvement of Bioinsecticides Production by Sporeless Bacillus thuringiensis Strains in Response to Various Stresses in Low Cost Medium. Curr Microbiol 62:1467-1477.

- Ben Khedher S, Zouari N, Messaddeq N, Schultz P, Jaoua S (2011b) Overproduction of delta-endotoxins by sporeless Bacillus thuringiensis mutants obtained by nitrous acid mutagenesis. Curr Microbiol 62:38-43.

- Demain AL (1995) Microbial secondary metabolism: The new frontier. In: W. Kuhn, H.P. Fiedler (eds) Sekundär Metabolismus bei Microorganismen. Altempo Verlag, Tübingen, pp 11-35.

- Desai SY, Shethna YI (1991) Production and formulation of Bacillus thuringiensis var. israelensis and B. sphaericus 1593. Indian J Med Res 93:318-323.

- Farrera RR, Pérez-Guevara F, de la Torre M (1998) Carbon: nitrogen ratio interacts with initial concentration of total solids on insecticidal crystal protein and spore production in Bacillus thuringiensis HD-73. Appl Microbiol Biotechnol 49:758-765.

- Ghribi D, Zouari N, Jaoua S (2004) Improvement of bioinsecticides production through mutagenesis of Bacillus thuringiensis by U.V. and nitrous acid affecting metabolic pathways and/or delta-endotoxin synthesis. J Appl Microbiol 97:338-346.

- Ghribi D, Zouari N, Jaoua S (2005) Improvement of bioinsecticides production through adaptation of Bacillus thuringiensis cells to heat treatment and NaCl addition. J Appl Microbiol 98:823-831.

- Ghribi D, Zouari N, Trigui W, Jaoua S (2007) Use of sea water as salts source in starch and soya bean based media, for the production of Bacillus thuringiensis bioinsecticides. Process Biochem 42:374-378.

- Içgen Y, Içgen B, Özcengiz G (2002) Regulation of crystal protein biosynthesis by Bacillus thuringiensis: II. Effects of carbon and nitrogen sources. Res Microbiol 153:605-609.

- Kanekar PP, Nilegaonkar SS, Sarnaik SS, Kelkar AS (2002) Optimization of protease activity of alkaliphilic bacteria isolated from an alkaline lake in India. Bioresour Technol 85:87-93.

- Khuri AI, Cornell JA (1996) Response Surfaces, Designs and Analyses. Marcel Dekker, New York.

- Kumar A, Sra K, Sangodkar UMX, Sharma VP (2000) Advances in the bio-control of mosquito vectors utilizing Bacillus sphaericus and Bacillus thuringiensis var. israelensis Proc. Natl Acad Sci India LXX 1-20.

- Lee HL, Seleena P (1991) Fermentation of a Malaysian Bacillus thuringiensis serotype H-14 isolate, a mosquito microbial control agent utilizing local wastes. Southeast Asian J Trop Med Public Health 22:108-112.

- Mathieu D, Nony J, Phan-Tan-Luu R (2000) NEMROD-W software. LPRAI, Marseille.

- Myers RH, Montgomery DC (1995) Response Surface Methodology: Process and Product Optimization Using Designed Experiments. Wiley, New York.

- Navon A (2000) Bacillus thuringiensis insecticides in crop protection - reality and prospects. Crop Prot 19:669-676.

- Özkan M, Dilek FB, Yetis Ü, Özcengiz G (2003) Nutritional and cultural parameters influencing antidipteran delta-endotoxin production. Res Microbiol 154:49-53.

- Prabakaran G, Balaraman K (2006) Development of a cost-effective medium for the large-scale production of Bacillus thuringiensis var. israelensis Biol Control 36:288-292.

- Ruzal SM, Alice AF, Sanchez-Rivas C (1994) Osmoresistance of spores from Bacillus subtilis and the effects of ssp mutations. Microbiology 140:2173-2177.

- Saalma HS, Foda MS, Dulmage HT, Sharaby EL (1983) Novel fermentation medium for production of delta endotoxin from Bacillus thuringiensis J Invertebr Pathol 41:8-19.

- Tokcaer Z, Bayraktar E, Mehmetoglu U, Özcengiz G, Alaeddinoglu NG (2006) Response surface optimization of antidipteran delta-endotoxin production by Bacillus thuringiensis subsp. israelensis HD 500. Process Biochem 41:350-355.

- Zouari N, Achour O, Jaoua S (2002a) Production of delta-endotoxin by Bacillus thuringiensis subsp. kurstaki and overcome of catabolite repression, by using highly concentrated gruel and fish meal media in 2 and 20 l fermenters. J Chem Technol Biotechnol 77:877-82.

- Zouari N, Ben Sik Ali S, Jaoua S (2002b) Production of deltaendotoxin by several Bacillus thuringiensis strains exhibiting various entomocidal activities towards Lepidoptera and Diptera in gruel and fish-meal media. Enzyme Microb Technol 31:411-418.

- Zouari, N.; Dhouib, A.; Ellouz, R.; Jaoua, S. (1998). Nutritional requirements of a strain of Bacillus thuringiensis subsp kurstaki and use of gruel hydrolysate, for the formulation of a new medium for delta-endotoxin production. Appl Biochem Biotechnol 69:41-52.

- Zouari, N.; Jaoua, S. (1999). Production and characterization of metalloproteases synthesized concomitantly with δ-endotoxin by Bacillus thuringiensis subsp. kurstaki strain grown on gruel-based medium. Enzyme Microb Technol 25:364-371.

Publication Dates

-

Publication in this collection

03 Feb 2014 -

Date of issue

Sept 2013

History

-

Received

04 Oct 2011 -

Accepted

13 Nov 2012