Abstract

Chitosanase production of Gongronella sp. JG cells immobilized in calcium alginate gel and polyurethane foam was compared with that of the free cells, there was a 60% increase in the enzyme yield (2429 U/L) compared to the highest yield obtained from free cells (1513 U/L). The optimal immobilization parameters (concentrations of sodium alginate, calcium chloride, bead inoculums, bead diameter, etc) for the enhanced production of chitosanase were determined as: sodium alginate 2% (w/v), 0.1 M calcium chloride, inoculum 10 mL beads to 100 mL production media and 2.7 mm bead diameter. Maximum chitosanase production was achieved with initial pH of 5.5 and temperature of 30 ºC. The alginate beads had well stability, retained 85% ability of enzyme production even after 7 cycles of repeated batch fermentation. These results showed the immobilization technique was a feasible and economical method for chitosansase production by Gongronella sp. JG.

chitosanase production; Gongronella sp. JG; cell immobilization; sodium alginate

Enhancement of chitosanase production by cell immobilization of Gongronella sp. JG

Pingping ZhangI,II; Wei ZhouI; Peng WangI; Li WangI; Mingli TangI

IKey Laboratory of Ion Beam Bioengineering, Chinese Academy of Sciences, Hefei, Anhui Province, P.R. China

IISchool of Life Science, Anhui University, Hefei, Anhui Province, P.R. China

Send correspondence to Send correspondence to: M. Tang Key Laboratory of Ion Beam Bioengineering Chinese Academy of Sciences, 230031 Hefei, Anhui Province, P.R. China E-mail: tangmingli100@hotmail.com

ABSTRACT

Chitosanase production of Gongronella sp. JG cells immobilized in calcium alginate gel and polyurethane foam was compared with that of the free cells, there was a 60% increase in the enzyme yield (2429 U/L) compared to the highest yield obtained from free cells (1513 U/L). The optimal immobilization parameters (concentrations of sodium alginate, calcium chloride, bead inoculums, bead diameter, etc) for the enhanced production of chitosanase were determined as: sodium alginate 2% (w/v), 0.1 M calcium chloride, inoculum 10 mL beads to 100 mL production media and 2.7 mm bead diameter. Maximum chitosanase production was achieved with initial pH of 5.5 and temperature of 30 ºC. The alginate beads had well stability, retained 85% ability of enzyme production even after 7 cycles of repeated batch fermentation. These results showed the immobilization technique was a feasible and economical method for chitosansase production by Gongronella sp. JG.

Key words: chitosanase production, Gongronella sp. JG, cell immobilization, sodium alginate.

Introduction

Chitosan, mainly obtained by deacetylation of chitin that has been extracted from an abundant of shrimp or crab shells, is a deactylated derivative of chitin and is part of the most abundant renewable biomass, next to cellulose, of the earth. Applications of chitosan have been developed in industries, such as food production and pharmaceutical industry (Choi et al., 2004; Streit et al., 2009; Bento et al., 2009). Moreover, chitosan oligosaccharides have recently received much attention because they perform various biological activities, such as inhibiting the growth of fungi and bacteria, activating immune response and exerting antitumour activity (Hadwiger et al., 1994; Suzuki et al., 1986; Ueno et al., 1997). Although it would be desirable to utilize chitosan extensively as a biomaterial, most chitosans are not being utilized due to their high molecular weights and high viscosity. Deacetylated chitosans are customarily produced by treating chitin in a concentrated alkaline solution (50%, w/v) and boiling it for several hours, or enzyme catalyzing the cleavage of β-1,4-linked glycosidic linkage by chitosanase (EC 3.2.1.132) which has been found in many micro-organisms, including viruses, bacteria and fungi (Alfonos et al., 1992; Kim et al., 2004; Park et al., 1999; Price et al., 1975; Sun et al., 2006; Zhu et al., 2003). Enzymatic processes to produce chitosan oligosaccharides are an ideal alternative compared to traditional chemical degradation which needs acid hydrolysis and results in low yields of oligosaccharides.

Microbial products are usually obtained from free or immobilized cells. The immobilized cell technology has several advantages over ordinary suspension culture systems, such as elimination the step of enzyme purification and extraction, higher enzyme activity after immobilization, greater resistance to environmental perturbations and lower cost. In addition, the immobilization support can be chosen with the desired geometry that provides greater ease of handling, better mass transfer characteristics and physical resistance (Hemachander and Bose, 2001). This has triggered a surge of research activity in this exciting and rapidly growing field. General immobilization techniques include the covalent attachment or adsorption to solid supports, entrapment within a gel lattice, microencapsulation within semi-permeable membranes and cross-linking to insoluble aggregates. There are various natural and synthetic polymers that have been used, such as ion-exchange resins, activated carbon (Grishin and Tuovinen, 1988), polyurethane foam BSP (Armentia and Webb, 1992), nicked alloy fiber (Gomez and Cantero, 2000), calcium alginate (Dias et al., 2000; Lancy et al., 1984), PVA-boric acid (Long and Huang, 2004). However, each has its drawbacks. One of the most suitable methods for cell immobilization is entrapment in calcium alginate, because this technique is simple and cheap. Sodium alginate is a readily available non-toxic biological material and is therefore suitable as an immobilization matrix for bio-molecules and microorganisms. Beads of calcium alginate prepared under mild conditions have been used extensively for microencapsulating and entrapping cells (Jamuna and Ramakrishna, 1992).

A lot of work has been carried out on chitosanase production in submerged fermentation. However, little information is available about immobilization of microbial cells for extracellular chitosanase production (Wu and Xia, 2000). Gongronella sp. JG is a novel chitosanase producing fungus isolated by our group (Yuan and Zhou, 2007). The previous study found that strain Gongronella sp. JG produced at least two chitosanase isoenzymes and the two enzymes had been purified and characterized (Wang et al., 2008; Zhou et al., 2008). In the present investigation, a successful attempt has been made to identify the process conditions optimal for the immobilization of Gongronella sp. JG in calcium alginate gel and to determine the operational stability of immobilized beads in the production of chitosanase in repeated batch fermentation.

Materials and Methods

Chemicals

Chitosan with DA85 (deacetylate degree) was purchased from the local suppliers in China. D-glucosamine was purchased from Sigma-Aldrich. All other reagents were of analytical grade. Colloidal chitosan was prepared according to the method described by Kurakake et al. (2000) with a little modification. Commercial chitosan (1 g, 85% deacetylated) was dissolved in water (10 mL) by adding acetic acid (0.285 mL). Then, the pH was adjusted to 5.5 and water was added to a total volume of 100 mL.

Microorganism

Gongronella sp. JG used in the study was isolated in our laboratory from a soil sample collected from Hefei, Anhui Province, China. It was identified by characteristic of morphologic and molecular analysis of 18S rDNA sequence. The stock culture was maintained on potato dextrose agar (PDA) slants which were inoculated and kept at 30 ºC for 120 h and then kept at 0-4 ºC until further use.

Immobilization of Gongronella sp. JG in calcium alginate beads

Gongronella sp. JG subcultured on PDA medium was used to prepare the spore suspension. The spore crop from each slant was scrapped into 20 mL of sterile distilled water using a sterile glass rod. The spore count was measured using Neubaeur's chamber and the spore suspension (1 x 107 spores/mLP) was used for preparing the beads.

The spore suspension was made by mixing spores with an equal volume (1:1v/v) of sodium alginate solution and stirred for 5 min. The mixed solution obtained was then placed in a syringe and allowed to drop in to a sterile CaCl2 solution that was stirred continuously. Alginate drops solidified upon contact with CaCl2, forming beads and thus entrapping spore cells. The beads were allowed to harden for several minutes and then washed with sterile water to remove redundant calcium ions and free cells. The calcium alginate beads with immobilized cells of Gongronella sp. JG were then used for submerged fermentation. The whole procedure of immobilization was carried out under sterile conditions. Unless otherwise specified, the parameters of immobilization were kept constant.

Immobilization of Gongronella sp. JG in polyurethane foam

The polyurethane foam in 4 mmx4mmx4mmwas used as the carrier of immobilized cell. 0.2 g polyurethane foam was added to 250 mL Erlenmeyer flasks containing 75 mL of PDA medium. The fermentation flasks were placed in an incubator shaker with an agitation rate of 150 rpm. After 10 h fermentation, washed the polyurethane foam with sterile water.

Fermentation

The immobilized cells prepared by the above methods (5, 10, 15 or 20 mL) were added to 100 mL of production medium (PM) in 250 mL Erlenmeyer flasks. Medium composition (g/L) was: glucose, 1; glutamic acid, 1.5; KH2PO4, 2; MgSO4, 0.2; pH 5.5. The flasks were incubated on a rotary shake (150 rpm) at 30 ºC for 84 h. Aliquots were withdrawn at regular time intervals of 12 h and the culture supernatant obtained after centrifugation at 10000 rpm for 20 min at 4 ºC was used as the enzyme preparation. Simultaneous experiments with free cells equivalent to those used in immobilized cultures were also conducted. The effectiveness factor of the immobilized system was defined as the ratio of chitosanase activity of the immobilized system to that of the free cells.

Optimization of fermentation parameters

Effect of different concentrations of sodium alginate on chitosanase production

In order to evaluate the influence of sodium alginate concentrations to chitosanase production, four different concentrations of sodium alginate (0.2-5%, w/v) were used for the preparation of beads. Fermentations were carried out using PM as described above.

Effect of different molarities of the calcium chloride on chitosanase production

To obtain beads with proper permeability and rigidity, the molarity of the calcium chloride needs to be optimized. For this purpose, different concentrations of sodium CaCl2 (0.03-0.5 M) were used to beads preparation. The subsequent fermentation procedure was carried out as mentioned earlier.

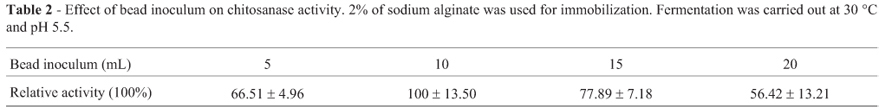

Effect of bead inoculum on chitosanase production

100 mL PM was inoculated with varying volumes of gel beads (5, 10, 15 and 20 mL), known as bead inoculum, and the fermentation was carried out till 96 h as described earlier.

Effect of different bead diameter on chitosanase production

The effect of bead size was studied for various bead diameter 2.7, 3.2, 3.9 and 4.2 mm. The beads inoculum used in these processes was 10 mL beads to 100 mL production media, and the fermentation was carried out as described earlier.

Effect of different temperature on chitosanase production

The effect of temperature on fermentations was carried out at various temperatures of 24 ºC, 27 ºC, 30 ºC, and 33 ºC for 84 h. Initial pH of the fermentation medium was 5.5, 2% (w/v) of sodium alginate, 10 mL beads with 2.7 mm bead diameter was used in 100 mL production media, and the fermentation was carried out as described earlier.

Effect of different initial pH on chitosanase production

The effect of initial pH was studied by conducting fermentation at various initial pH of 4.5, 5.0, 5.5 and 6.0 with 2% (w/v) Calcium alginate. These flasks were incubated at 30 ºC, 10 mL bead with 2.7 mm diameter was used in 100 mL production media, and the fermentation was carried out as described earlier.

Repeated batch fermentation

Repeated batch fermentation was conducted with the immobilized cells by running the fermentation for 84 h. At the end of each cycle, the PM was decanted, the beads containing immobilized cells were thoroughly washed with sterile distilled water, and a fresh PM was added to start a new round fermentation.

Determination of chitosanase activity

Chitosanase activity was assayed using colloidal chitosan as the substrate. The reaction mixture consisted of 1.8 mL 1% colloidal chitosan in 50 mM sodium acetate buffer (pH 5.5) and 0.2 mL enzyme solution. After the mixture had been incubated at 55 ºC for 30 min, hydrolysis reaction was terminated. Then 2 mL dinitrosalicylic acid reagent was added into the mixture and boiled for 10 min. After being chilled and centrifuged to remove insoluble chitosan, the resulting adducts of reducing sugar were measured by spectrophotometry at 540 nm. The amount of chitosanase which could produce 1 µM of reducing sugar per min was taken as one unit. D-glucosamine was used as the calibration standard to measure chitosanase activity (Dygert and Li, 1965).

Results and Discussion

Selection of immobilization materials

The results of chitosanase production from free and immobilized cells using various entrapment techniques were shown in Figure 1. Both free and immobilized cells showed maximum enzyme production at 84 h. The immobilized cells with calcium alginate as carrier had higher activity than those with polyurethane foam carrier and free cells. The beads were stable even beyond six cycles of reusability transfer. These results were in accordance with other studies on immobilization (Ellaiah et al., 2004; Najafpour et al., 2004). The immobilized cells with polyurethane foam have preferable life-time, but their activity is the lowest. The main reason might be that the agglomeration of PVA gel beads cause lower nourishment circulation and restrict the transfer of nutrients into the gel. Although PVAboric acid method is simple and economical, two potential problems with this technique are the agglomeration of PVA gel beads and the toxicity of saturated boric acid which have not been completely eliminated until now (Lozinsky and Plieva, 1998). We did not choose PVA-boric acid method because chitosanase is mainly used in food and pharmacy industry. Since the enzyme production was a preferential target than the others in this study, sodium alginate was considered to be the best matrix for production of chitosanase. Therefore, cells entrapped by sodium alginate were used for further optimization studies in this work.

Optimization of immobilization in calcium alginate

Optimizing the parameters of immobilization offers the advantage of improving the bead characteristics, such as permeability and rigidity. Figure 2 showed the pattern of chitosanase production at various sodium alginate concentrations. The highest chitosanase yield was obtained with beads prepared using 2% (w/v) sodium alginate. At higher concentration of sodium alginate the pellet rigidity was improved but the chitosanase production decreased due to diffusion limitations that restricted the transfer of nutrients into the gel and enzyme out of the gel into the medium (Ellaiah and Prabhakar, 2004). On the other hand, beads prepared using lower concentrations of sodium alginate were fragile and the cells were easily leakage into the medium. These beads using 2% (w/v) sodium alginate were quite stable and did not show any tendency to dissolve.

The effect of CaCl2 concentration on chitosanase production was shown in Figure 3. As in the case of sodium alginate, lower concentration of CaCl2 may result in increased leakage of cells into the fermentation medium owing to the decreased rigidity of beads. On the other hand, an increase in CaCl2 concentration from 0.03 M to 0.1 M minimized the cell leakage and consequently increased the chitosanase yield. But at higher concentration of CaCl2, the enzyme yield was declined. Considering maximum enzyme yield, 0.1 M CaCl2 was chosen as the optimum for the formation of beads with suitable rigidity and permeability. The mechanical strength of alginate beads is highly dependent on CaCl2 concentration of the gelation solution and the use of concentrated CaCl2 solutions has a higher effect on the efficiency of immobilized system (Konsoula and Liakopoulou-Kyriakides, 2006). The results can be explained by the fact that when the sodium alginate concentration is increased beyond 2%, the thickness of the membrane capsule decreases (Kurakake and Yo-u, 2000), and this is presumably due to the fact that increasing the number of biopolymer molecules per unit solution, the binding sites for Ca2+ ions also increase. As a result, a more densely crosslinked gel structure is probably formed, and consequently results in the formation of thinner walls. The dense membrane is expected to create diffusion resistance through the beads which result in lower product formation as nutrients and substrates are restricted to diffuse easily to the cells. The 2% sodium alginate concentration was observed to produce higher chitosanase probably be due to less cross-linking of the alginate molecules taking place forming less densely packed three-dimensional lattices from the outermost layer to the core of the drop and resulted in easy diffusion of nutrients through the beads, thus promoted growth of Gongronella sp. JG and increased productivity. Similar results were reported by Najafpour and Habibollah (2004) in ethanol production and Bandi et al. (2003) in neomycin production when using calcium alginate matrices.

In brief, the results indicated that chitosanase production depended on the rigidity and permeability of the beads. The constraints created inside the calcium alginate beads by the immobilization procedure led to changes in the micro environmental conditions which could modify the physiological and morphological behavior of a microorganism compared to that of the free cell cultures. By only adjusting the conditions of immobilization, it is possible to substantially influence the ratio in which the individual metabolites are synthesized. Proper rigidity and permeability promote chitosanase production. This means that there is a relationship between cell immobilization and chitosanase production.

Effect of initial pH and temperature

The effect of various initial pH on the chitosanase production of the immobilized Gongronella sp. JG during the batch fermentation was illustrated in Figure 4. The maximum chitosanase production for initial pH 5.5 was 12 h shorter compared with the other initial pH. It is possible that the higher initial pH bring too much stress on the organism metabolic abilities (Wu and Xia, 2000). At initial pH 5.5, cells start to utilize glucose earlier and at a faster rate than at other initial pH. Thus, initial environment of pH 5.5 encourages the Gongronella sp. JG to consume glucose rapidly contributing to the maximum chitosanase production. Further increase in initial pH beyond 5.5 does not improve the chitosanase production. This initial pH is also in agreement with the optimum pH of chitosanase from the organism Gongronella sp. JG.

The chitosanase production at temperature of 24, 27, 30, 33 ºC was different: the highest chitosanase production was obtained at 30 ºC, dropped to about 85% of the highest level at 27 and 33 ºC, and the lowest was at 24 ºC (lower than 20% of the highest). Temperature is one of the important factors that affect the growth of microorganism and its enzymes production. Most species have a charac-teristic range of temperature in which they can grow, but they do not grow at the same rate over the whole of temperature range. In this case, the total enzyme activity is related to initial cell concentration, cell growth, enzyme production and enzyme stability in the process of fermentation, and the highest chitosanase activity was obtained at 30 ºC.

Effect of bead diameter

The chitosanase production for the four different bead diameters was shown in Table 1. Maximum chitosanase production was attained for the 2.7 mm bead diameter. A further increase in the bead diameter resulted in a decrease of chitosanase production. Smaller bead diameter produced higher chitosanase production, might due to an increase in the surface volume ratio (Ellaiah and Prabhakar, 2004). The results seem to be in agreement with work performed by Abdel-Naby and Mok (1992) who found that the lactic acid increased as bead diameter decreased. But a balance must be reached among the ease handling of beads manufacture, better mass transfer characteristics, physical resistance and the fermentation production, and 2.7 mm was selected as our suitable choice.

Effect of bead inoculum

Different volumes of 2% alginate gel (5, 10, 15 and 20 mL) were added to 100 mL PM. Results indicated that the enzyme production increased from 5 mL to 10 mL, but decreased with increase in bead inoculum thereafter (Table 2). Dobreva et al. (1996) and Angelova et al. (1998) had also reported the decrease in enzyme production with increasing gel volume. The decreased enzyme activity with increase in bead inoculum might be due to competition between cells because of which the nutrient concentration available in the flasks might not have been sufficient for optimal growth, leading to low enzyme production. Moreover, the competition between cells would have lead to rapid use of nutrient resulting in smaller duration of enzyme activity. Hence, the variant with 10 mL bead inoculum appeared to present the best conditions for enzyme synthesis.

Operational stability of immobilized cells

The possibility of re-using immobilized cells of Gongronella sp. JG for chitosanase production was studied seven cycles of fermentation. The duration of a fermentation cycle selected for repeated batch fermentation was 84 h. The immobilized system retained catalytic activity for a long time period and was reused successfully for the production of chitosanase (Figure 5). After the fifth cycle, there was about 5% loss in activity with each consecutive use till the seventh cycle. Even after seven successive and efficient fermentation operations, the alginate beads had good stability and maintained 85% of the enzyme yield obtained in the first cycle. The decrease in enzyme yield with successive fermentation might be due to the loss of cell viability. The reuse ability of the present immobilization system was in accordance with that reported in other findings (Angelova et al., 1998; Hemachander et al., 2001). The greater stability of the entrapped cells might be ascribed to the stabilizing effects of immobilization.

Conclusion

This study showed that our method was feasible to produce chitosanase using immobilized cell. Maximum chitosanase could be obtained with optimal immobilization parameters of 2% sodium alginate, 0.1 M calcium chloride, 2.7 mm bead diameter, initial pH of 5.5 and temperature of 30 ºC.

Based on the above results, it could be concluded that calcium alginate served as a nice matrix for entrapment of fungal cells for chitosanase production. The alginate beads had well stability and also retained the ability of enzyme production up to 7 cycles of reusability transfer. The operational stability of this biocatalyst system indicated the possibility of the application of this immobilized system in semi-continuous processes for chitosanase production.

Acknowledgments

This work was supported by Natural Science Foundation of Anhui Province of China (11040606M78 and 1208085MC52).

Submitted: December 4, 2010

Approved: July 2, 2012

All the content of the journal, except where otherwise noted, is licensed under a Creative Commons License CC BY-NC

- Abdel-Naby M, Mok K, Lee C (1992) Production of organic acid from enzymatic hydrolyzate of starch by immobilized lactic acid bacteria. In: UNIDO Proceedings, Korea, pp 227-243.

- Alfonos C, Martines M, Reyes F (1992) Purification and properties of two endochitosananse from Mucor rouxii implication on its cell wall degradation. FEMS Microbiol Lett 95:187-194.

- Angelova M, Sheremetska P, Lekov M (1998) Enhanced polymethylgalacturonase production from Aspergillus niger 26 by calcium alginate immobilization. Process Biochem 33:299-305.

- Armentia H, Webb C (1992) Ferrous sulphate oxidation using Thiobacillus ferrooxidans cell immobilized in polyurethane foam support particles. Appl Microbiol Biotechnol 36:697-700.

- Bandi S, Kunamneni A, Poluri E (2003) Investigation on neomycin production with immobilized cell of Streptomyces marinensis Vuv-5 in calcium alginate matrix. AAP Pharm Sci Tech 4:54-57.

- Bento RA, Stamford TLM, Campos-Takaki GM, Stamford TCM, Souza EL (2009) Potential of chitosan from Mucor rouxxi UCP 064 as alternative natural compound to inhibit Listeril Monocytogenes Braz J Microbiol 40:583-589.

- Choi Y, Kim E, Piao Z, Yun Y, Shin Y (2004) Purification and characterization of chitosanase from Bacillus sp Strain KCTC 0377BP and its application for the production of chitosan oligosaccharides. Appl Environ Microbiol 70:4522-4531.

- Dias JCT, Rezende RP, Linard VR (2000) Biodegradation of acetonitrile by cells of candida Candida guilliermondii UFMG-Y65 immobilization in alginate, k-carrageenan and citric pectin. Braz J Microbiol 31:61-66.

- Dobreva E, Ivanova V, Tonkova A, Radulova E (1996) Influence of the immobilization conditions on the efficiency of a-amylase production by Bacillus licheniformis. Process Biochem 31:229-234.

- Dygert S, Li LH, Florida D, Thoma JA (1965) Determination of reducing sugar with improved precision. Anal Biochem 13:367-374.

- Ellaiah P, Prabhakar T, Ramakrishna B, Thaer TA, Adinarayana K (2004) Production of lipase by immobilized cells of Aspergillus niger Process Biochem 39:525-528.

- Gomez JM, Cantero D, Webb C (2000) Immobilization of Thiobacillus ferrooxidans cells on nickel alloy fibre for ferrous sulfate oxidation. Appl Microbiol Biotechnol 54:335-340.

- Grishin S, Tuovinen OH (1988) Fast kinetics of Fe2+ oxidation in packed-bed reactors. Appl Environ Microbiol 54:3092-3100.

- Hadwiger L, Ogawa T, Kuyama H (1994) Chitosan polymer sizes effective in inducing phytoalexin accumulation and fungal suppression are verified with synthesized oligomers. Mol Plant Microbe Interact 7:531-533.

- Hemachander C, Bose N, Puvanakrishnan R (2001) Whole cell immobilization of Ralstonia pickettii for lipase production. Process Biochem 36:629-633.

- Jamuna R, Ramakrishna SV (1992) Continuous synthesis of thermo±e a-amylase by Bacillus cells immobilized in calcium alginate. Enzyme Microb Technol 14:36-41.

- Kim PI, Kang TH, Chung KJ, Kim IS, Chung K (2004) Purification of a constitutive chitosanase produced by Bacillus sp. MET 1299 with cloning and expression of the gene. FEMS Microbiol Lett 240:31-39.

- Konsoula Z, Liakopoulou-Kyriakides M (2006) Thermostable a-amylase production by Bacillus subtilis entrapped in calcium alginate gel capsules. Enzyme Microb Technol 39:690-696.

- Kurakake M, Yo-u S, Nakagawa K, Sugihara M, Komaki T (2000) Properties of chitosanase from Bacillus cereus S1. Curr Microbiol 40:6-9.

- Lancy ED, Tuovinen OH (1984) Ferrous iron oxidation by Thiobacillus ferrooxidans immobilised in calcium alginate. Appl Environ Microbiol 20:94-99.

- Long Z, Huang Y, Cai Z, Wei C, Fan O (2004) Immobilization of Acidithiobacillus ferrooxidans by a PVA-boric acid method for ferrous sulphate oxidation. Process Biochem 39:2129-2133.

- Lozinsky VI, Plieva FM (1998) Poly(vinyl alcohol) cryogels employed as matrices for cell immobilization: 3. Overview of recent research and developments. Enzyme Microb Technol 23:227-242.

- Najafpour G, Habibollah Y, Ismail KSK (2004) Ethanol fermentation in an immobilized cell reactor using Saccharomyces cerevisiae Bioresour Technol 92:251-260.

- Park JK, Shimono K, Ochiai N, Shigeru K, Kurita M, Ohta Y, Tanaka K, Matsuda H, Kawamukai M (1999) Purification, characterization, and gene analysis of a chitosanase (ChoA) from Matsuebacter chitosanotabidus 3001. J Bacteriol 181:6642-6649.

- Price J, Storck R (1975) Production, purification and characterization of an extracellular chitosanase from Streptomyces. J Bacteriol 124:1574-1585.

- Streit F, Koch F, Laranjeira MCM, Ninow JL (2009) Production of fungal chitosan in liquid cultivation using apple pomace as substrate. Braz J Microbiol 40:20-25.

- Sun Y, Liu W, Han B, Zhang J, Liu B (2006) Purification and characterization of two types of chitosanase from a Microbacterium sp. Biotechnol Lett 28:1393-1399.

- Suzuki K, Mikami T, Okawa Y, Tokoro A, Suzuki S, Suzuki M (1986) Anti-tumor effect of hexa-N-acetylchito-hexaose and chitohexaose. Carbohydr Res 151:403-408.

- Ueno K, Yamaguchi T, Sakairi N, Nishi N, Tokura S (1997) Antimicrobial activity by fractionated chitosan oligomers. In: Domard A, Roberts GAF, Varum KM (eds), Advances in Chitin Science. Jacques Andre Publisher, Lyon, pp 156-161.

- Wang J, Zhou W, Yuan H, Wang YJ (2008) Characterization of a novel fungal chitosanase Csn2 from Gongronella sp. JG. Carbohydr Res 343:2583-2588.

- Wu MB, Xia LM, Cen PL (2000) Studies on simultaneous production of chitosanase and chitsan degradation in situ with Trichoderma reesei in convoluted fibrous bed bioreactor. Chinese J Biotech 16:368-372 [Article in Chinese]

- Yuan H, Zhou W, Wang J, Zhang S, Yao J (2007) Enhancement of Gongronella sp. JG chitosanase production by ion beam implantation. Plasma Sci Technol 9:115-118.

- Zhou W, Yuan H, Wang J, Yao J (2008) Production, purification and characterization of chitosanase produced by Gongronella sp. JG. Lett Appl Microbiol 46:49-54.

- Zhu X, Wu X, Dai Y (2003) Fermentation conditions and properties of a chitosanase from Acinetobacter sp C-17. Biosci Biotech Biochem 67:284-290.

Publication Dates

-

Publication in this collection

09 Apr 2013 -

Date of issue

2013

History

-

Received

04 Dec 2010 -

Accepted

02 July 2012