Abstract

Paper aims

To define and evaluate the environmental performance of the implementation of reverse logistics (RL) for empty pesticide plastic containers (EPPC) in Brazil through the Campo Limpo System (CLS).

Originality

Discussion about the implementation of RL for the development of sustainable systems, through the identification of environmental impacts associated with RL of EPPC by means of Life Cycle Assessment (LCA).

Research method

CLS is described and used to quantify the potential environmental impacts of the RL chain of EPPC waste management by using the LCA methodology. The analysis comprehends the situations prior and post implementation of the CLS, it takes into account container manufacturing, transportation and end-of-life.

Main findings

Implementation of the CLS resulted in a reduction in nine assessed environmental impacts categories, ranging from a reduction of 79% to 26% in potential impacts. The stage leading to the largest contribution to environmental impacts is the manufacturing of EPPC. For end-of-life options, recycling proved to be the best option to lower environmental impacts.

Implications for theory and practice

Results show that the public policy was environmentally effective given that current activities in EPPC management led to lower environmental impacts enabling the development of a sustainable supply chain.

Keywords

Agricultural plastic waste; Packaging waste management; Waste recovery; End of life; Shared responsibility. Environmental management

1. Introduction

1.1. Reverse logistics of empty pesticides containers

Brazil is one of the largest pesticide consumers in the world, which stems from the country’s large agricultural production (Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis, 2019Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis – IBAMA. (2019). Histórico de comercialização. Retrieved in 21 August 2021, from http://www.ibama.gov.br/agrotoxicos/relatorios-de-comercializacao-de-agrotoxicos#historicodecomercializacao

http://www.ibama.gov.br/agrotoxicos/rela...

). Intensive use of pesticide products raises environmental concerns regarding the impacts of their production, transportation and end of life (EoL) of packaging materials due to soil contamination and human toxicity potential (Guyton et al., 2015Guyton, K. Z., Loomis, D., Grosse, Y., El Ghissassi, F., Benbrahim-Tallaa, L., Guha, N., Scoccianti, C., Mattock, H., & Straif, K. (2015). Carcinogenicity of tetrachlorvinphos, parathion, malathion, diazinon, and glyphosate. The Lancet. Oncology, 16(5), 490-491. http://dx.doi.org/10.1016/S1470-2045(15)70134-8. PMid:25801782.

http://dx.doi.org/10.1016/S1470-2045(15)...

). Concomitantly, high plastic consumption in agriculture by itself is a source of environmental concern due to management and residue destination issues (Blanco et al., 2018Blanco, I., Loisi, R. V., Sica, C., Schettini, E., & Vox, G. (2018). Agricultural plastic waste mapping using GIS: a case study in Italy. Resources, Conservation and Recycling, 137, 229-242. http://dx.doi.org/10.1016/j.resconrec.2018.06.008.

http://dx.doi.org/10.1016/j.resconrec.20...

; Lagarda-Leyva et al., 2019Lagarda-Leyva, E. A., Morales-Mendoza, L. F., Ríos-Vázquez, N. J., Ayala-Espinoza, A., & Nieblas-Armenta, C. K. (2019). Managing plastic waste from agriculture through reverse logistics and dynamic modeling. Clean Technologies and Environmental Policy, 21(7), 1415-1432. http://dx.doi.org/10.1007/s10098-019-01700-5.

http://dx.doi.org/10.1007/s10098-019-017...

). Moreover, the large volume used requires logistics, specifically on transportation and packaging which, on their own, generates relevant economic and environmental impacts due to the short lifespan of packaging (Barros et al., 2018Barros, M. V., Salvador, R., Piekarski, C. M., & de Francisco, A. C. (2018). Mapping of main research lines concerning life cycle studies on packaging systems in Brazil and in the world. The International Journal of Life Cycle Assessment, 24, 1429-1443. http://dx.doi.org/10.1007/s11367-018-1573-2.

http://dx.doi.org/10.1007/s11367-018-157...

). To address this issues, circular economy strategies can be employed since this concept comprehends the end of useful life management of products and their reinsertion in the supply chain (Agrawal & Singh, 2019Agrawal, S., & Singh, R. K. (2019). Analyzing disposition decisions for sustainable reverse logistics: Triple Bottom Line approach. Resources, Conservation and Recycling, 150, 104448. http://dx.doi.org/10.1016/j.resconrec.2019.104448.

http://dx.doi.org/10.1016/j.resconrec.20...

). The process of reinserting products in the supply chain is done through reverse logistics (RL) to ensure operational efficiency and a sustainable chain (Oliveira & Camargo, 2014Oliveira, A. L. R., & Camargo, S. G. C. (2014). Logística reversa de embalagens de agroquímicos: identificação dos dos determinantes de sucesso. Interciencia, 39(11), 780-787.).

The importance of an adequate EoL management system for packaging materials for pesticides, used in the agricultural sector, is evidenced by the creation of specific waste management programs throughout the world, such as Pamira (Germany), CleanFARMS (Canada) and Sigfito (Spain). In 2000, Brazil adopted the Pesticide Law 9,974 that was the base for the Brazilian Waste Management Policy (PNRS in Portuguese) (Brasil, 2010Brasil. (2010, August 3). Institui a Política Nacional de Resíduos Sólidos; altera a Lei nº 9.605, de 12 de fevereiro de 1998; e dá outras providências (Lei nº 12.305, de 2 de agosto de 2010). Diário Oficial da República Federativa do Brasil. Retrieved in 21 August 2021, from http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm

http://www.planalto.gov.br/ccivil_03/_at...

). This environmental oriented legislation introduces the concept of extended producer responsibility and brings light to a compulsory reverse logistics (RL) to products such as, lamps, batteries, electronic products and lubricant oils, but also for empty pesticide containers. For empty pesticide containers, the EoL is a mandatory and shared responsibility between several public and private agents, including: the final consumer, the manufacturer/importer, retailers and the public regulatory agency. The mentioned Solid Waste policy establishes the final consumer (farmers) as the responsible for rinsing, decommissioning and storing (up to one year) the containers after use. The effectiveness of this type of system is directly affected by the final disposal of the retrieved products, which depend on the adequate rinsing of the containers (Agrawal & Singh, 2019Agrawal, S., & Singh, R. K. (2019). Analyzing disposition decisions for sustainable reverse logistics: Triple Bottom Line approach. Resources, Conservation and Recycling, 150, 104448. http://dx.doi.org/10.1016/j.resconrec.2019.104448.

http://dx.doi.org/10.1016/j.resconrec.20...

; Picuno et al., 2020Picuno, C., Alassali, A., Sundermann, M., Godosi, Z., Picuno, P., & Kuchta, K. (2020). Decontamination and recycling of agrochemical plastic packaging waste. Journal of Hazardous Materials, 381, 120965. http://dx.doi.org/10.1016/j.jhazmat.2019.120965.

http://dx.doi.org/10.1016/j.jhazmat.2019...

). The pesticide industries, represented by the National Institute for Empty Packages Processing or InpEV (acronym in Portuguese), are responsible for the reverse logistics of empty containers which include multiple functions, namely, receiving the empty containers, identifying the sites to send these containers, certifying the adequate container delivery, organizing itinerant collection alternatives for remote locations and also educating farmers on the importance of the collection and container valorisation program. Producers that are more environmentally conscious tend to return containers respecting the timelines instead of discarding them on the environment (Jack et al., 2010Jack, E. P., Powers, T. L., & Skinner, L. (2010). Reverse logistics capabilities: antecedents and cost savings. International Journal of Physical Distribution & Logistics Management, 40(3), 228-246. http://dx.doi.org/10.1108/09600031011035100.

http://dx.doi.org/10.1108/09600031011035...

). Extended producer responsibility reduces plastic waste in agriculture (De Lucia & Pazienza, 2019De Lucia, C., & Pazienza, P. (2019). Market-based tools for a plastic waste reduction policy in agriculture: a case study in the south of Italy. Journal of Environmental Management, 250, 109468. http://dx.doi.org/10.1016/j.jenvman.2019.109468. PMid:31505381.

http://dx.doi.org/10.1016/j.jenvman.2019...

). The regulatory agency is responsible for licensing the companies for collection and transportation of empty pesticide containers and supervises the entire process (Instituto Nacional de Processamento de Embalagens Vazias, 2016Instituto Nacional de Processamento de Embalagens Vazias – inpEV. (2016). Relatório da sustentabilidade 2016. São Paulo. Retrieved in 21 August 2021, from https://inpev.org.br/relatorio-sustentabilidade/2016/pt/index.html

https://inpev.org.br/relatorio-sustentab...

).

Specifically for the RL of empty containers, a system called “Campo Limpo” (CLS) was created for the purpose of enabling the farmer to return these containers. In this system, the farmers return the empty pesticide containers to collection points, central units or itinerant collections. When the containers arrive in collection points, they are transported to central units and then directed for their EoL destinations (either incineration or recycling)

1.2. Life cycle assessment

Presently, the published Life Cycle Assessment (LCA) work on transportation impacts of post-consumer agricultural plastic containers is not vast in Brazil. Studies that evaluate end of life of plastics in agriculture (Gu et al., 2017Gu, F., Guo, J., Zhang, W., Summers, P. A., & Hall, P. (2017). From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. The Science of the Total Environment, 601-602, 1192-1207. http://dx.doi.org/10.1016/j.scitotenv.2017.05.278. PMid:28605837.

http://dx.doi.org/10.1016/j.scitotenv.20...

; Urreaga et al., 2020Urreaga, J. M., Beltrán, F. R., Acosta, J., Aguinaco, T., Fonseca, C., Ochoa, A., Oliet Palá, J. A., González-Sánchez, C., & de la Orden, M. U. (2020). Tube shelters from agricultural plastic waste: an example of circular economy. Journal of Cleaner Production, 268, 122401. http://dx.doi.org/10.1016/j.jclepro.2020.122401.

http://dx.doi.org/10.1016/j.jclepro.2020...

) indicate that adopting circular economy practices is environmentally positive. The study by Treenate et al. (2017)Treenate, P., Limphitakphong, N., & Chavalparit, O. (2017). A complete life cycle assessment of high density polyethylene plastic bottle. IOP Conference Series. Materials Science and Engineering, 222(1), 012010. http://dx.doi.org/10.1088/1757-899X/222/1/012010.

http://dx.doi.org/10.1088/1757-899X/222/...

, evaluated the environmental performance, from cradle to grave, of high-density polyethylene (HDPE) used in packages of lubricants oils in Thailand. Results indicate that the stages most contributing to the overall impact are extraction of raw materials and pre-processing. In the study from Dahlbo et al. (2018)Dahlbo, H., Poliakova, V., Mylläri, V., Sahimaa, O., & Anderson, R. (2018). Recycling potential of post-consumer plastic packaging waste in Finland. Waste Management, 71, 52-61. http://dx.doi.org/10.1016/j.wasman.2017.10.033. PMid:29097129.

http://dx.doi.org/10.1016/j.wasman.2017....

, recycling of waste from post-consumer plastic containers in Finland in the municipal solid waste system was evaluated, results show that plastic waste is a useful raw material. Relative to the EoL, Arena et al. (2003)Arena, U., Mastellone, M. L., & Perugini, F. (2003). Life cycle assessment of a plastic packaging recycling system. The International Journal of Life Cycle Assessment, 8(2), 92-98. http://dx.doi.org/10.1007/BF02978432.

http://dx.doi.org/10.1007/BF02978432...

, and Perugini et al. (2005)Perugini, F., Mastellone, M. L., & Arena, U. (2005). A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environment and Progress, 24(2), 137-154. http://dx.doi.org/10.1002/ep.10078.

http://dx.doi.org/10.1002/ep.10078...

, evaluated the potential environmental impacts of domestic empty plastic containers in Italy, comparing environmental indicators for recycling with those of landfills and incineration facilities, concluding that recycling is always preferable. Aryan et al. (2019)Aryan, Y., Yadav, P., & Samadder, S. R. (2019). Life Cycle Assessment of the existing and proposed plastic waste management options in India: a case study. Journal of Cleaner Production, 211, 1268-1283. http://dx.doi.org/10.1016/j.jclepro.2018.11.236.

http://dx.doi.org/10.1016/j.jclepro.2018...

evaluated EoL management of plastics in India, also considering recycling, landfills and incineration and found that incineration with energy production was the best management option.

When looking at Brazilian studies within the topic of EoL management, it is clear that, although rarely focusing on empty containers, some studies using LCA for some of the products mentioned in the PNRS were performed. Souza et al. (2016)Souza, R. G., Clímaco, J. C. N., Sant’Anna, P., Rocha, T. B., Valle, R. A. B., & Quelhas, O. L. G. (2016). Sustainability assessment and prioritisation of e-waste management options in Brazil. Waste Management (New York, N.Y.), 57, 46-56. http://dx.doi.org/10.1016/j.wasman.2016.01.034. PMid:26852754.

http://dx.doi.org/10.1016/j.wasman.2016....

, evaluated electrical and electronic equipment waste management options in Rio de Janeiro to find the most efficient e-waste collection system. His work recommends the use of a hybrid collection system with delivery points at stores, subway stations and neighbourhoods with integrated social enterprises and cooperatives to promote a more comprehensive recyclability of electronic components. Oliveira & Magrini (2017)Oliveira, M. C., & Magrini, A. (2017). Life cycle assessment of lubricant oil plastic containers in Brazil. Sustainability, 9(4), 576. http://dx.doi.org/10.3390/su9040576.

http://dx.doi.org/10.3390/su9040576...

, evaluated different options for the EoL of lubricant oil plastic containers finding the potential of reduction on the environmental impacts when deposition in industrial landfills is avoided. Zappe et al. (2015)Zappe, A. L., Silva Trentin, A. W., Rodriguez, A. L., & Rodríguez López, D. A. (2015). Diagnóstico da logística reversa de lâmpadas por meio da avaliação de ciclo de vida. Revista CIATEC-UPF, 7(1), 13. http://dx.doi.org/10.5335/ciatec.v7i1.4328.

http://dx.doi.org/10.5335/ciatec.v7i1.43...

focused on RL and EoL options for fluorescent lamps and found that lamp transportation had the largest contribution to the overall environmental impact amongst the evaluated chain stages. Also, Oliveira (2019)Oliveira, A. B. (2019). Avaliação do ciclo de vida de cenários de logística reversa de embalagens de agrotóxicos no Brasil (Tese de doutorado). Universidade Estadual Paulista “Júlio de Mesquita Filho”, Bauru. evaluated RL for EPPC in four central units located in two different states and found that the distance between these units and end-of-life destinations concentrated most potential environmental impacts. However, the findings from Oliveira (2019)Oliveira, A. B. (2019). Avaliação do ciclo de vida de cenários de logística reversa de embalagens de agrotóxicos no Brasil (Tese de doutorado). Universidade Estadual Paulista “Júlio de Mesquita Filho”, Bauru. result from a reduced number of central units (4 in total) and their specific end of life destinations. In the present study the practices for whole State of São Paulo were assessed, covering 38 collection points, 14 central units and several end-of-life facilities.

1.3. Aim of this work

None of the studies described above focus on quantification of the potential benefits brought by the implementation of a national policy for reverse logistic of empty pesticide containers used for crop protection in Brazil. The use of plastics in agriculture is rarely addressed in rural waste management research and is an important component for the promotion of sustainable practices in agriculture (Altieri, 2018Altieri, M.A. (2018). Agroecology: the science of sustainable agriculture (2nd ed.). Boca Raton: CRC Press.). The assessment of environmental impacts associated with national waste management practices, may consolidate the advantages brought by the PNRS. This can also be relevant for identifying options for improvements within the Brazilian current RL activities for EPPC. For the purpose of quantifying the environmental impacts, a LCA study of EPPC RL for the current practices within the state of São Paulo (Brazil), including the situations pre–CLS and post-CLS, was carried out. The boundaries considered include the container material production, manufacturing and transportation from the collection points until the valorisation/deposition sites (recycling, incineration and landfill).

Brazil is relying on pesticide consumption to maintain a high agricultural crop productivity. The large amount of pesticide usage generates a proportional amount of plastic waste used in the containers. A RL program that adequately treats these containers is fundamental to lower the environmental impacts associated with pesticide use. This work demonstrates the importance of RL for EPPC and, through a quantitative analysis of associated impacts for the disposal of EPPC, reaffirm the need for appropriate RL programs, through the quantification of the potential impacts. The results presented in this work bring light to improvements in circular economy practices for general end of life management of EPPC. They may serve as reference for multiple audiences. For public policy makers, results reaffirm the importance of adequate legislation and adequate reverse logistics management. This is done by quantifying the reduction in the environmental impacts by using the well-known LCA methodology. However, a larger audience may also benefit from the findings of this work. For instance, by recognizing the environmental benefits of processing practices for use and disposal of EPPC and by knowing the mitigation impacts brought by the use of recycled materials (such as COEX) into pesticide packaging containers.

2. Material and methods

The environmental assessment was performed according to the requirements of ISO 14040 and 14044 on LCA (International Organization for Standardization, 2006aInternational Organization for Standardization – ISO. (2006a). ISO 14040: environmental management: life cycle assessment: principles and framework (testimony of ISO). Genève: ISO., bInternational Organization for Standardization – ISO. (2006b). ISO 14044: environmental management: life cycle assessment: requirements and guidelines (testimony of ISO). Genève: ISO.).

2.1. Goal and scope definition

This work aims to assess the environmental impacts associated with the RL of EPPC made from two different materials (HDPE and COEX) and used as packaging for crop protection pesticides in the state of São Paulo, Brazil. It considers the pre and post-CLS implementation systems and uses inventory data from the year 2017. The functional unit (FU) is a rectangular model EPPC with a capacity of 20 liters of pesticide and the reference flow is 1.218 kg for both containers made of polymeric materials (HDPE and COEX-Co-extruded polyethylene). The LCA considers the boundaries from cradle to EoL and evaluates three options for end of life management options for containers. The boundaries of this study comprehend several activities, here designed by stages:

-

Stage A: the extraction of materials and production of the container;

-

Stage B: compaction and transportation of the empty container;

-

Stage C: the end of life options for the empty containers.

The LCA is attributional and no allocation was required. This is to say that no partitioning of the mass and energy inputs and/or outputs flows is needed when only one product is analyzed. The geographic boundary related to the collection, recycling and sanitary landfill of EPPC is the whole State of São Paulo and the timeframe considered is the volume of empty pesticide containers collected and processed in 2017 by 38 collections points, 14 central collections, 4 recycling plants and 3 incineration plants. There are 89 sanitary landfills in the State of São Paulo (Companhia Ambiental do Estado de São Paulo, 2015Companhia Ambiental do Estado de São Paulo – CETESB. (2015). Inventário estadual de resíduos sólidos urbanos 2015. São Paulo.) and for the purpose of this study, it is assumed that EPPCs outside the CLS are transported to landfills via the municipal waste collection system.

All scenarios consider the extraction of HDPE and the production of the container by blow molding. For COEX, 80% (mass) comes from the recycling of EPPC made from HDPE and the remaining comes from extracted raw material and it is manufactured with the processes of co-extrusion and blow molding (Oliveira et al., 2011Oliveira, A. B. S., Cantinho, A. M., Souza, G. A., & Chagas, R. S. (2011). Produção, consumo e destinação de embalagens de agrotóxicos no Vale do Paraíba. In XV Encontro Latino Americano de Iniciação Científica e XI Encontro Latino Americano de Pós-graduação. São José dos Campos: Universidade do Vale do Paraíba. Retrieved in 21 August 2021, from http://www.inicepg.univap.br/cd/INIC_2011/anais/arquivos/0126_0067_01.pdf

http://www.inicepg.univap.br/cd/INIC_201...

). In Brazil, the collection of previously separated empty containers is made by type of packaging material, making use of big bags and using heavy trucks. Upon completion of the full volume of a heavy truck these are sent to the central unit. At the central unit, containers are compacted and sent off for recycling or incineration. This work considers the data provided by InpEV that 94% of the EPPC returned to the system, from which 91% are recycled and 9% are incinerated (Instituto Nacional de Processamento de Embalagens Vazias, 2018Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2018). Dados atualizados do desempenho e dos impactos do Sistema. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/sistema-campo-limpo/em-numeros/

http://www.inpev.org.br/sistema-campo-li...

). Packages not integrated into the CLS (remaining 6%) were considered to be sent to municipal solid waste (MSW) landfills by trucks in accordance with the standard end of life practices for plastic materials (Al-Salem et al., 2009Al-Salem, S. M., Lettieri, P., & Baeyens, J. (2009). Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Management, 29(10), 2625-2643. http://dx.doi.org/10.1016/j.wasman.2009.06.004. PMid:19577459.

http://dx.doi.org/10.1016/j.wasman.2009....

; Lazarevic et al., 2010Lazarevic, D., Aoustin, E., Buclet, N., & Brandt, N. (2010). Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resources, Conservation and Recycling, 55(2), 246-259. http://dx.doi.org/10.1016/j.resconrec.2010.09.014.

http://dx.doi.org/10.1016/j.resconrec.20...

).

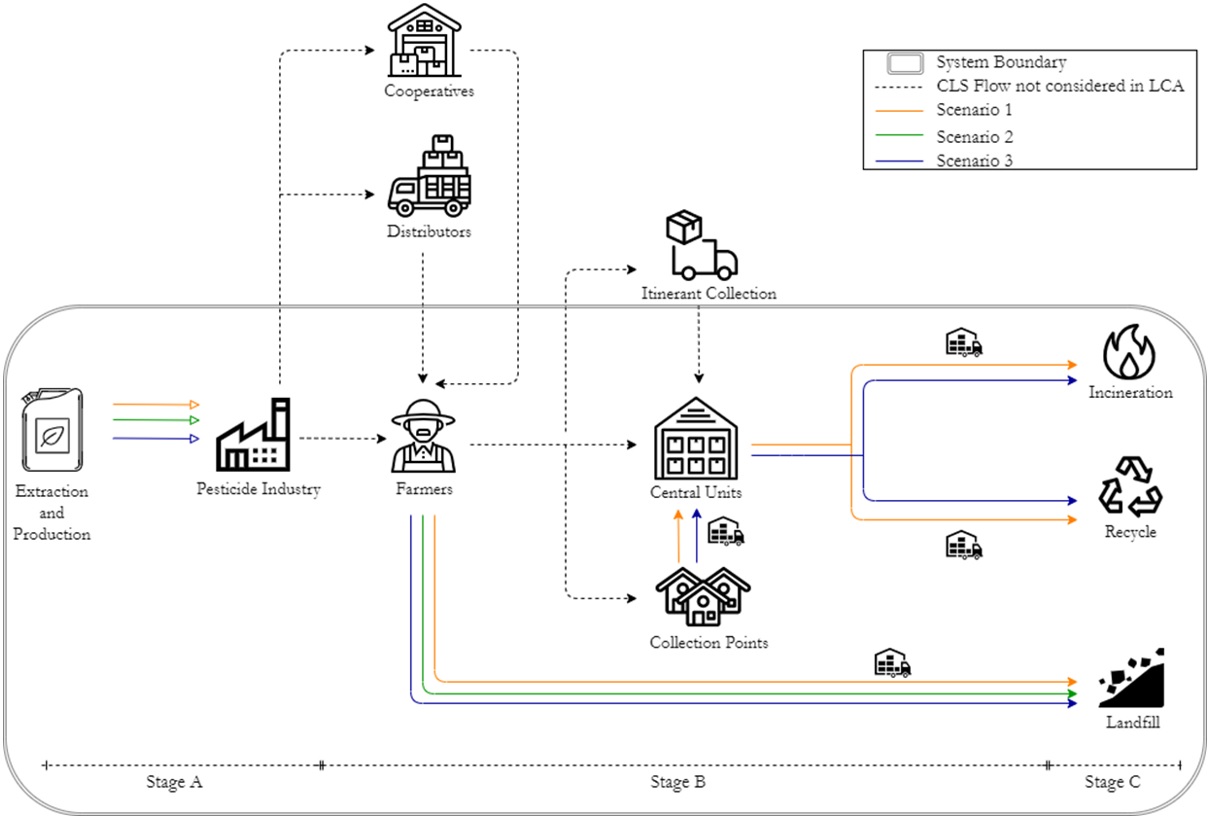

This work analyzes and compares three scenarios, one pre-CLS and the other two post-CLS, as illustrated in Figure 1. The baseline scenario (Scenario 1) is the one currently taking place in Brazil by using the most updated information (year 2017) for EPPC data from Marsola & Oliveira (2018)Marsola, K. B., & Oliveira, A. L. R. (2018). Caracterização da logítica reversa de emabalgens vazias de agroquímicos no Estado de São Paulo. In Anais do XXVI Congresso de Iniciação Científica Unicamp. Campinas: Unicamp. https://doi.org/10.20396/revpibic.v0i0.id

https://doi.org/10.20396/revpibic.v0i0.i...

. EoL options. Scenario 2 evaluates the situation taking place before the adoption of the CLS. The CLS disregards the estimated 20 to 25% of the volume of pesticides used in Brazil, which are originated from non-legal sources (Instituto Nacional de Processamento de Embalagens Vazias, 2018Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2018). Dados atualizados do desempenho e dos impactos do Sistema. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/sistema-campo-limpo/em-numeros/

http://www.inpev.org.br/sistema-campo-li...

), to cover this gap, Scenario 3 considers that 25% of the EPPC are sent off to MSW landfills and the remaining enters the CLS.

-

Scenario 1 (S1, baseline): considers that 94% of EPPC enters the CLS and the remaining 6% is sent to landfill following the same route as the MSW. From the 94%, 91% is sent off to recycling and 9% to incineration for both the HDPE and the COEX container;

-

Scenario 2 (S2, prior to CLS): all EPPC are made of HDPE and were sent off to the closest landfill following the same route as the MSW;

-

Scenario 3 (S3, a fraction of EPPC is sent to MSW landfills): considers that 25% of the EPPC do not enter the CLS and, instead, are sent to landfills while the remaining 75% enters the CLS, following the same path as in Scenario 1.

In this work it is assumed that EPPC (both from HDPE and COEX) are recycled and used as raw materials for the production of other consumer goods. In respect to the application of materials resulting from HDPE and COEX recycling they may include, production of corrugated ducts, plastic lids and pipes (Instituto Nacional de Processamento de Embalagens Vazias, 2019Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2019). Relatório de sustentabilidade. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/index

http://www.inpev.org.br/index...

). The incineration of EPPC is used for energy production, which is incorporated into the Brazilian electricity grid. With regards to EPPC incineration and landfilling, it was considered that the amount of pesticide left in the empty container is 5% mass of the empty container material. Due to the uncertainty associated with this value a sensitivity analysis to show the influence of this uncertainty in the overall result for the environmental impact was performed.

Excluded from the system boundaries are the infrastructure (such as the construction of manufacturing facilities), capital goods (as e.g. the vehicle fleet used in transportations) and all transportations of the containers filled with pesticides needed to arrive to the farmer. In addition, this study does not account for container lids (made of polypropylene), container labels and big bags used for transportation from collection points to central collection since they are found to be marginal in terms of the contribution to the environmental impact, in line with the study from Oliveira and Magrini (2017)Oliveira, M. C., & Magrini, A. (2017). Life cycle assessment of lubricant oil plastic containers in Brazil. Sustainability, 9(4), 576. http://dx.doi.org/10.3390/su9040576.

http://dx.doi.org/10.3390/su9040576...

.

2.2. Inventory analysis

All inventory data used in the LCA modeling are provided in Table 1. The description on the subsequent subsections provide further information on how these values were obtained. EPPC data was collected directly from InpEV which is the national institute responsible for containers collection.

Data and Ecoinvent databases used to model life cycle inventory. Values reported to the FU = 1.218kg.

2.2.1. Stage A: extraction and production

Primary information, namely for, mass and composition of containers, number of containers processed by each central collection, locations for the central collection points and recycling facilities, was collected either in published literature by InpEV or directly by interviewing stakeholders involved in the CLS for São Paulo. EPPC data was collected directly from InpEV which is the institute responsible for container collection. Background data was retrieved from the Ecoinvent database (version 3.3), for instance, to model the impact of the extraction and production of materials that compose the containers. Excluded from the boundaries are all activities prior to the transportation of EPPC from collection points, namely, transport of containers to the filling with pesticides, filling with pesticides, transport to the sales point, label and lid production and use of the pesticides by the farmer and posterior transportation to collection points since these are related to the regular use of the product and not necessary to assess waste management strategies for EPPC.

HDPE extraction was modeled by using background data from the Ecoinvent 3.3 inventory database described in Table 1. For the production of HDPE containers, the material losses were assumed to be 3% mass (in granulate production) according to Mermerta & Babuna (2019)Mermerta, M., & Babuna, F. G. (2019). Life cycle environmental impact analysis of HDPE packaging materials for different disposal options. In N. Balkaya & S. Guneysu (Eds.), Recycling and reuse approaches for better sustainability, environmental science and engineering (pp. 55-61). Cham: Springer. http://dx.doi.org/10.1007/978-3-319-95888-0_5.

http://dx.doi.org/10.1007/978-3-319-9588...

and 0.3% mass in the blow molding process in line with losses considered in the Ecoinvent database. COEX containers are registered trademarks (Ecoplástica®) composed of three layers, the outer layer is virgin HDPE (5% of total container mass), the intermediate layer is composed of recycled HDPE (80% in mass) and the inner layer is virgin HDPE (15% in mass). For COEX container production, two processes were considered: co-extrusion and blow molding. Material losses in these processes were considered to be 3.1% for co-extrusion and 0.3% for blow molding (in line with losses considered in the Ecoinvent database).

Data for the rest of world (RoW) was used for the items in which Brazilian specific data is not available in Ecoinvent 3.3. database. But for electricity and water inputs, the database was changed to respond to the Brazilian case. For all of the processes using electricity, the Brazilian electricity matrix, available in the Ecoinvent database, for the year 2014, was considered. This is because there was no significant change in the mix of the Brazilian electricity matrix from 2014 to 2017 (Empresa de Pesquisa Energética, 2015Empresa de Pesquisa Energética – EPE. (2015). Balanço Energético Nacional 2015. Relatório Síntese: Ano base 2014. Retrieved in 21 August 2021, from https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-127/topico-95/Relatório Síntese 2015.pdf

https://www.epe.gov.br/sites-pt/publicac...

, 2018Empresa de Pesquisa Energética – EPE. (2018). Balanço Energético Nacional 2018. Relatório Síntese: Ano base 2017. Retrieved in 21 August 2021, from https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-303/topico-397/Relatório Síntese 2018-ab 2017vff.pdf

https://www.epe.gov.br/sites-pt/publicac...

).

2.2.2. Stage B: transportation

The EPPC transportation circuit comprehends the transport from the collection points to central units where they will be compacted, the transport from central units to recyclers or incinerators and, for the case where containers will be landfilled, the transport is made by the lorry used for collecting municipal solid waste. At first, containers are transported in vehicles with a load capacity ranging from 7.5 to 16 tons. The same type of vehicles are used to transport containers from central collections to their EoL destination. The vehicle fleet considered has an average age of 8 years (equivalent to the EURO 3). It was considered that the fleet consumes high-sulphur diesel, since low-sulfur content is used in Brazil for fleets produced after 2012. Although these vehicles have a 14.5 ton capacity, containers that leave the collection points are not compacted which reduces cargo to 1.5 tones due to lack of storage space, when containers are compacted the load transported can be as high as 7.5 to 8.5 tones (Faria & Pereira, 2012Faria, A. C., & Pereira, R. S. (2012). O processo de logística reversa de embalagens de agrotóxicos: um estudo de caso sobre o InpEV. Organizações Rurais & Agroindustriais., 14(1), 127-141. Retrieved in 21 August 2021, from http://www.fca.unesp.br/Home/Extensao/ProjetoColetaSeletiva52/politica_residuos_solidos.pdf

http://www.fca.unesp.br/Home/Extensao/Pr...

). The transportation to landfills is done using lorries used for municipal waste collection with a 21-ton capacity.

The inventory between the collection points and central units was built considering the amount of EPPC processed in 2017 (Marsola & Oliveira, 2018Marsola, K. B., & Oliveira, A. L. R. (2018). Caracterização da logítica reversa de emabalgens vazias de agroquímicos no Estado de São Paulo. In Anais do XXVI Congresso de Iniciação Científica Unicamp. Campinas: Unicamp. https://doi.org/10.20396/revpibic.v0i0.id

https://doi.org/10.20396/revpibic.v0i0.i...

), and the distances between the 37 collection points and 14 central units of the state of São Paulo (provided in Table SM1). The road distances between collection points and central units were obtained using the Google Maps tool.

The inventory between central units and the facilities for the EoL of EPPC was estimated based on the identification of recyclers and incineration plants partners of InpEV (Instituto Nacional de Processamento de Embalagens Vazias, 2018Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2018). Dados atualizados do desempenho e dos impactos do Sistema. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/sistema-campo-limpo/em-numeros/

http://www.inpev.org.br/sistema-campo-li...

). Within the state of São Paulo there are four recycling points and three incineration plants, Table SM2 provides the distance between the central units and these facilities. The modelled inventory for transportation (expressed in kg.km) (Table 1) is calculated by considering the distance between each central unit and the corresponding recycling plants and then multiplying each distance by the share of the total mass being processed by each unit (Marsola & Oliveira, 2018Marsola, K. B., & Oliveira, A. L. R. (2018). Caracterização da logítica reversa de emabalgens vazias de agroquímicos no Estado de São Paulo. In Anais do XXVI Congresso de Iniciação Científica Unicamp. Campinas: Unicamp. https://doi.org/10.20396/revpibic.v0i0.id

https://doi.org/10.20396/revpibic.v0i0.i...

). The value (kg.km) for each central was added up to account for the total weighted average value for transportation between central and recycling plants. The same calculation procedure was done for the value used for transportation between central units and incineration plants. No values were calculated for Scenario 2, because in this case all containers are sent to landfills. The electricity used for container compacting at the central units and the transports using freight trucks of the containers to landfills compose Stage B for scenarios 1 and 3.

2.2.3. Stage C: end of life

There are three end of life options for EPPC in Scenarios 1 and 3. These comprehend recycling, incineration and landfill for each one of the two scenarios. For Scenario 2, landfill is the only option assessed. The current options for recycling of EPPC requires a proper rinsing by the producers, since containers with any remaining pesticide residue are considered hazardous waste and require special transportation and disposal (incineration), which brings an additional cost increase (Jin et al., 2018Jin, S., Bluemling, B., & Mol, A. P. J. (2018). Mitigating land pollution through pesticide packages: the case of a collection scheme in Rural China. The Science of the Total Environment, 622-623(56), 502-509. http://dx.doi.org/10.1016/j.scitotenv.2017.11.330. PMid:29220774.

http://dx.doi.org/10.1016/j.scitotenv.20...

). When producers adequately rinse the containers, usually right before the pulverization process, they become residue free and can be classified as regular plastic waste and processed by the recycling facilities. EPPCs that is destined for landfills are the ones in Scenario 2 (prior to CLS) or the ones that escape the CLS system. These EPPCs are assumed to be sent off to municipal landfills.

Primary data, namely for, mass and composition of containers, number of containers processed by each central collection, locations for the central collection points and recycling facilities, was collected either in published literature by InpEV (Instituto Nacional de Processamento de Embalagens Vazias, 2018Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2018). Dados atualizados do desempenho e dos impactos do Sistema. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/sistema-campo-limpo/em-numeros/

http://www.inpev.org.br/sistema-campo-li...

) or directly by interviewing stakeholders involved in the CLS for São Paulo. Background data was retrieved from the Ecoinvent database (version 3.3).

2.3. Impact assessment

Life-cycle impact assessment (LCIA) was performed using the SimaPro 9.3.0.2. A total of 13 midpoint impact categories were assessed. The impact categories were chosen to reflect the main environmental issues related to the product/service system. Following the recommendations from the ILCD Handbook (European Union, 2010European Union. (2010). General guide for Life Cycle Assessment: detailed guidance (1st ed.). Luxembourg. https://doi.org/10.2788/38479.

https://doi.org/10.2788/38479...

), since there is no impact methodology specific for Brazil. The methods selected for the evaluation of the environmental impacts was the ReCiPe Midpoint (H) (version 1.13, World Recipe H) for the categories, human toxicity (HT), photochemical oxidant formation (POF), particulate matter formation (PMF), terrestrial ecotoxicity (TET), marine ecotoxicity (MET), water depletion (WD) and fossil depletion (FD). From the IPCC 2013 method (Stocker et al., 2013Stocker, T. F., Qin, D., Plattner, G. K., Tignor, M. M. B., Allen, S. K., Boschung, J., Nauels, A., Xia, Y., Bex, V., & Midgley, P. M. (2013). Climate change 2013: the physical science basis. Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (1586 p.). Cambridge: IPCC.) was used for Climate Change (CC), the CML 2001 method (Guinée et al., 2002Guinée, J., Gorrée, M., Heijungs, R., Huppes, G., Kleijn, R., Koning, A., van Oers, L., Wegener Sleeswijk, A., Suh, S., Udo de Haes, H. A., Bruijn, H., van Duin, R., & Huijbregts, M. A. (2002). Handbook on life cycle assessment: operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background. Dordrecht: Springer.) was used to evaluate Terrestrial Acidification (TA) and Ozone Depletion (OD) 5 years, categories, from EDIP 2003 (Hauschild & Potting, 2005Hauschild, M., & Potting, J. (2005). Spatial differentiation in Life Cycle impact assessment - The EDIP2003 methodology. Danish Environmental Protection Agency, 80, 195.) we performed Freshwater Eutrophication (FE) and marine eutrophication (ME) categories, and USEtox method (Rosenbaum et al., 2008Rosenbaum, R. K., Bachmann, T. M., Gold, L. S., Huijbregts, M. A. J., Jolliet, O., Juraske, R., Koehler, A., Larsen, H. F., MacLeod, M., Margni, M., McKone, T. E., Payet, J., Schuhmacher, M., Van De Meent, D., & Hauschild, M. Z. (2008). USEtox - The UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. The International Journal of Life Cycle Assessment, 13(7), 532-546. http://dx.doi.org/10.1007/s11367-008-0038-4.

http://dx.doi.org/10.1007/s11367-008-003...

) was used to evaluate freshwater ecotoxicity (FET). These impact categories are being currently used for the Brazil context (Grael et al., 2021Grael, P. F. F., Oliveira, L. S. B. L., Oliveira, D. S. B. L., & Bezerra, B. S. (2021). Life cycle inventory and impact assessment for an asphalt pavement road construction: a case study in Brazil. The International Journal of Life Cycle Assessment, 26(2), 402-416. http://dx.doi.org/10.1007/s11367-020-01842-5.

http://dx.doi.org/10.1007/s11367-020-018...

).

2.4. Analysis of sensitive cases

A sensitivity analysis was performed using two parameters considered to be uncertain but relevant for the present study. First, the influence of varying the amount of pesticide left in the EPPC that is sent for incineration or landfill was analyzed. The value of 5% of the total mass of “empty container” was changed due to uncertainty about farmers' return practices to 10%. The other parameter studied was the distance between collection points, central units and containers EoL destinations. This distance was changed to the minimum possible values, this means that all EPPC were considered to take the shortest possible route, meaning that all EPPC travels from the collection point to the nearest central unit and from there to the nearest EoL destination.

Data for the rest of world (RoW aims to reveal the most influential parameters that may affect the overall impacts results. No uncertainty analysis was carried out. This is mainly due to the fact that primary data used (from the different agents in the reverse logistics chain) is not vast to perform a robust uncertainty analysis that could capture variations in the modelled the impacts.

3. Results and discussion

The impact categories for the three scenarios (S1 to S3) were evaluated for the two materials (HDPE and COEX) used as EPPC as shown in Figure 2. The figure presents results normalized from -1 to 1 within each impact category for all scenarios assessed. Results show that the worse environmental impact results are found for S2 in which all containers are produced from virgin HDPE and are sent off to landfills. This scenario contributes the most for 11 of the 13 categories analyzed. In contrast, S1 shows a better environmental contribution when containers are made of COEX. Negative values show reduced environmental burdens due to the positive effect of using recycled material in container production.

Results for all scenarios using the impact assessment methodology. Values for environmental impacts were normalized. HDPE-S1 (HDPE scenario 1), HDPE-S2 (HDPE scenario 2), HDPE-S3 (HDPE scenario 3), COEX-S1 (COEX scenario 1), COEX-S3 (COEX scenario 3).

In the following, the three stages evaluated are explored. Stage A has the largest contribution to the overall impact in all scenarios regardless of the type of material used for the production of EPPC. Stage B has the second largest contribution in S1, whereas for Scenarios 2 and 3 the second largest contribution is in Stage C. The most beneficial impact results came from the reduction in impacts due to the valorization of EPPC at the end of its life and the use of recycled material for their production.

Stage A assesses the production of EPPC. When it is made out of COEX (contains 80% recycled material) the impact is smaller when compared to the production of HDPE (Table 2). The categories CC, POF and FD appear to be negative with COEX in Scenarios 1 and 3 because recycled material avoids the usage of fossil raw materials that play a major role in the manufacturing of plastics. The contribution of HDPE, is higher in 8 categories. In this analysis, the manufacturing process for COEX expends slightly more energy than that of HDPE, however it is offset by the reduction in energy spent for raw material extraction.

Stage B comprehends transportation but also includes the compaction of EPPC in the central unit. In scenarios 1 and 3 most of the EPPC is sent to recycling and, as expected, this path represents the largest impact due to transportation (Table 3). The largest contributors, in the two scenarios evaluated, are the central units in Paraguaçu Paulista and Bilac. Paraguaçu Paulista processes the largest volume of EPPC and is 500 km away from incinerators and recyclers, which made this central unit responsible for about 18% of total impacts on each of the routes. On the other hand, central units that contribute less to impacts are those that require less transportation and the amount of EPPC processed is among the smallest (as observed in Table SM3 to Table SM6).

It must be highlighted that despite the fact that the State of São Paulo has all the units (collection points, central units, recyclers and incinerators) necessary for the processing of EPPC, the load at the Bilac and Paraguaçu Paulista plants demonstrate the emergency for environmental impact reduction strategies. Collected data for the last ten years (Figure SM1) shows an increase in the crop area in the State of São Paulo and also a growth of the partners integrating the CLS. Despite this, it is observed a decrease in the number of central units and collection points since 2011.

Another aspect that deserves a deeper look, regarding the environmental strategy, is the current distance between the EPPC EoL units and the agricultural sites. The EPPC valorization and end-of-life units are all located in the South and Southeast of the country (same region of São Paulo), however, most of the agricultural production is taking place at the Brazilian Midwest and the last agricultural frontier being explored is in the north and northeast of the country. This entails that often an EPPC to be valorized travels distances exceeding 2000 km. These factors increase transportation and processing costs, which in turn increase the cost of the recycled plastics to values similar to those of virgin plastics (Urreaga et al., 2020Urreaga, J. M., Beltrán, F. R., Acosta, J., Aguinaco, T., Fonseca, C., Ochoa, A., Oliet Palá, J. A., González-Sánchez, C., & de la Orden, M. U. (2020). Tube shelters from agricultural plastic waste: an example of circular economy. Journal of Cleaner Production, 268, 122401. http://dx.doi.org/10.1016/j.jclepro.2020.122401.

http://dx.doi.org/10.1016/j.jclepro.2020...

) The reduction in freight distances through the decentralization of collection points was indicated as a positive factor for the reduction in environmental impacts in (Oliveira, 2019Oliveira, A. B. (2019). Avaliação do ciclo de vida de cenários de logística reversa de embalagens de agrotóxicos no Brasil (Tese de doutorado). Universidade Estadual Paulista “Júlio de Mesquita Filho”, Bauru.). This fact, although not surprising, is in line with our results on mentioning that the reduction in freight distances, through the decentralization of collection points, was indicated as a positive factor for the reduction in environmental impacts.

From Table 4 it is shown that for Stage C recycling is the EoL option with the lowest environmental impact, while incineration shows the worse contribution for S1 and landfill for S3. Results show that the recycling or incineration of EPPC (S1 and S3) have contributed to the reduction of generated impacts when compared to S2. As expected, when possible, recycling is the best end-of-life destination. For S1, some of the impact categories present negative values (namely, CC, TA, ME, POF, PMF, FET and FD) representing reduced impacts due to the recycling of plastic within the production chain.

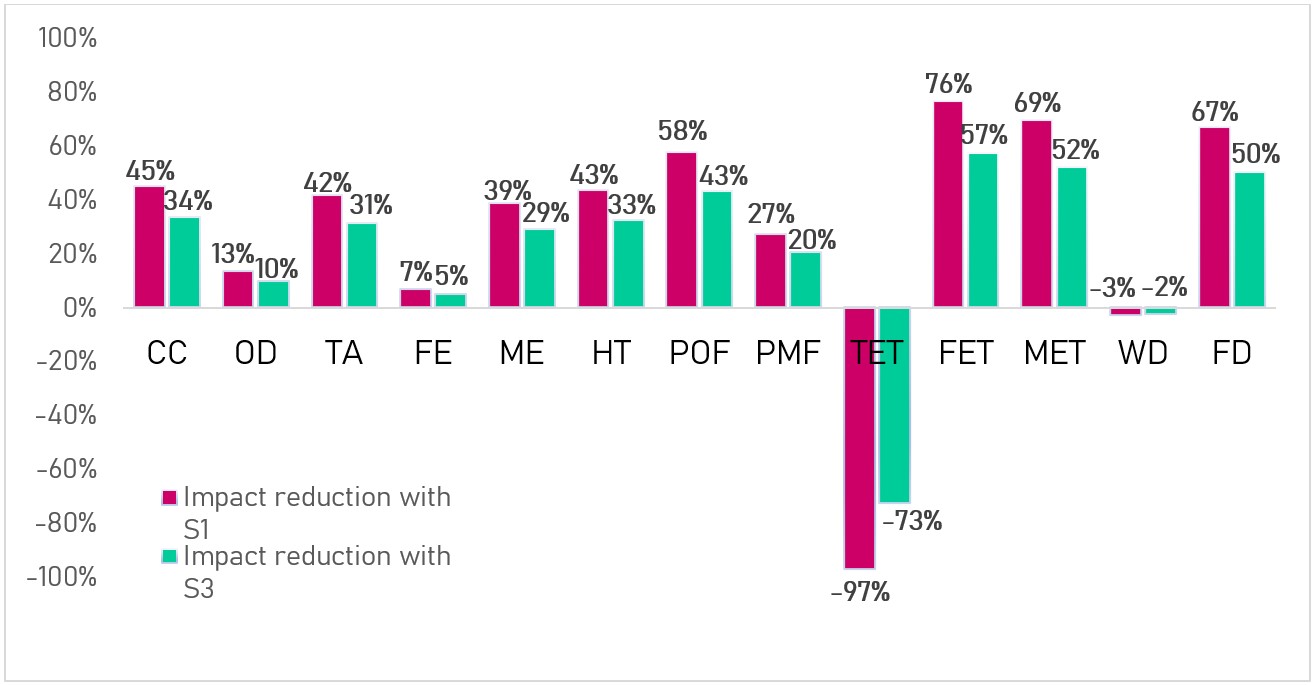

Results for S1 indicate EPPC incineration to be the larger contributor for environmental impacts while for S3 it is landfills. This is because the amount of landfilled containers is comparatively larger in S3 when compared to Scenario 1. In S1, 6% of the overall containers are landfilled while in Scenario 3 the value is 31%. Still comparing HDPE scenarios 1 and 3, both had significant gains when compared to S2. Figure 3 shows the reduction in impact categories post-CLS for S1 and S3, values are relative to the situation pre-CLS or S2. The calculated values show the relative change resulting from S1 and S3 when compared to the impacts from the situation prior to the CLS (S2). Positive values indicate relative reduction in potential impacts and negative values indicate potential increase in impacts in comparison with S2. From the 13 categories analyzed, 11 of them had reduced environmental impacts with the use of RL brought by the CLS.

Comparison between reduction in impact categories for S1 and S3 (HDPE). Climate change (CC), ozone depletion (OD), terrestrial acidification (TA), freshwater eutrophication (FE), marine eutrophication (ME) human toxicity (HT), photochemical oxidant formation (POF), particulate matter formation (PMF), terrestrial ecotoxicity (TET), freshwater ecotoxicity (FET), marine ecotoxicity (MET), water depletion (WD) and fossil depletion (FD).

Impact category HT associated with the release of substances that can cause harm to humans if inhaled, ingested or absorbed by the body was reduced by 33% for S3 and 43% for S1. Ozone formation in the soil due to nitrogen oxides and volatile organic compounds is measured by POF and was reduced by 58% for S1 and 43% for S3. FET and MET measure the potential contamination by toxic substances in freshwater and marine environments, respectively. These were both reduced by 76% and 69% respective for S1 and 57% and 52% for S3. This is likely due to recycling and incineration increasing the electricity matrix energy use after CLS implementation, with one of the major sources of electricity in Brazil being hydroelectric power. This increase in energy use is likely to be the reason why after CLS the impact category TET also increased (97% for S1 and 73% for S3). WD represents the environmental impacts associated with a decrease in freshwater availability and a slight increase was noticed as 3% for S1 and 2% for S3.

The adoption of a more environmentally friendly container (COEX) was only possible after the implementation of the collection system, since it is as a result of this policy that HDPE containers are recycled. Moreover, even when comparing the use of HDPE containers in S1 with COEX in S3, the recycled container was shown to have a lower environmental impact despite the increase in EPPC being sent to landfills (worst post-use scenario). It is important to highlight that the production of a COEX container is only possible due to the implementation of the PNRS. Besides removing potential hazardous residues from the environment, the recycling of EPPC also has coeffects already established in the published literature such as job creation, sustainable development and improving industry competitiveness (Andreoni et al., 2015Andreoni, V., Saveyn, H. G., & Eder, P. (2015). Polyethylene recycling: waste policy scenario analysis for the EU-27. Journal of Environmental Management, 158, 103-110. http://dx.doi.org/10.1016/j.jenvman.2015.04.036. PMid:25976302.

http://dx.doi.org/10.1016/j.jenvman.2015...

). Plastic residue recycling has been indicated as a circular economy approach with the potential to reduce waste (Rentizelas et al., 2018Rentizelas, A., Shpakova, A., & Mašek, O. (2018). Designing an optimised supply network for sustainable conversion of waste agricultural plastics into higher value products. Journal of Cleaner Production, 189, 683-700. http://dx.doi.org/10.1016/j.jclepro.2018.04.104.

http://dx.doi.org/10.1016/j.jclepro.2018...

) and being capable of producing plastics with good material properties (Briassoulis et al., 2013Briassoulis, D., Hiskakis, M., & Babou, E. (2013). Technical specifications for mechanical recycling of agricultural plastic waste. Waste Management, 33(6), 1516-1530. http://dx.doi.org/10.1016/j.wasman.2013.03.004. PMid:23561796.

http://dx.doi.org/10.1016/j.wasman.2013....

; Picuno et al., 2020Picuno, C., Alassali, A., Sundermann, M., Godosi, Z., Picuno, P., & Kuchta, K. (2020). Decontamination and recycling of agrochemical plastic packaging waste. Journal of Hazardous Materials, 381, 120965. http://dx.doi.org/10.1016/j.jhazmat.2019.120965.

http://dx.doi.org/10.1016/j.jhazmat.2019...

). The results from Lazarevic et al (2010)Lazarevic, D., Aoustin, E., Buclet, N., & Brandt, N. (2010). Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resources, Conservation and Recycling, 55(2), 246-259. http://dx.doi.org/10.1016/j.resconrec.2010.09.014.

http://dx.doi.org/10.1016/j.resconrec.20...

showed that recycling is generally the less impactful option, and this is relevant for several environmental impact categories, including climate change, acidification potential, eutrophication potential and residual solid waste reduction. These findings were also seen in this work. Another example is the study in Oliveira and Magrini (2017)Oliveira, M. C., & Magrini, A. (2017). Life cycle assessment of lubricant oil plastic containers in Brazil. Sustainability, 9(4), 576. http://dx.doi.org/10.3390/su9040576.

http://dx.doi.org/10.3390/su9040576...

, which also concluded that higher levels of plastics recycling and incineration are environmentally preferable. In the study in Briassoulis et al. (2014)Briassoulis, D., Hiskakis, M., Karasali, H., & Briassoulis, C. (2014). Design of a European agrochemical plastic packaging waste management scheme - Pilot implementation in Greece. Resources, Conservation and Recycling, 87, 72-88. https://doi.org/10.1016/j.resconrec.2014.03.013.

https://doi.org/10.1016/j.resconrec.2014...

which analyzed EPPC RL in Greece, results indicated that recycling and producer training are fundamental for the appropriate disposal. These results contribute to understanding the importance of a correct end of life destination by the producers, in which recycling and production of less environmentally impactful containers are favored (COEX).

Results from the sensitivity analysis, presented in Table 5, shows a small variation in most of the impact categories assessed when the volume of residual pesticide in the container increases from 5% to 10%. A difference of more than 10% is found in S1 and S2 for both materials in one category, ozone depletion. Sensitivity analysis results considering the shortest distance travelled between central units and collection points for EPPCs showed changes below 7% for all impact categories.

Here, it is timely to note that a sensitivity analysis was performed to depict the influence of certain changes in parameters, namely, travel distances and volume of residual pesticides left at the empty container. However, as explained above, these parameters seem not to have a significant contribution to the majority of the environmental impact categories.

Producer behavior directly affects the effectiveness of the RL since the quantity and quality of the returned EPPC depend on the proper rinsing of the containers. Adequate rinsing and return of EPPC can affect the amount of residual pesticide in the containers which increase significantly the potential environmental impacts. Finally, it should be mentioned that this study focuses on the system analysis of reverse logistics within which health risks are excluded and only LCA impacts are assessed. Nevertheless, it is assumed that EPPC waste fractions are handled by the normative proposed by InpEV to avoid any potential human risk.

4. Conclusions, limitations and future research

This paper presents past and present end of life management of EPPC in the state of São Paulo, Brazil. Through the use of LCA, the environmental impacts of practices before the implementation of the CLS (applicable to national solid waste management strategies) and after its implementation, are assessed to highlight the environmental benefits to EPPC management operations. In Brazil, EPPC RL is mandatory, contributing to a sustainable supply chain through the reinsertion of recycled material as raw material for other products and also providing the appropriate destinations. Additionally, this enables the reuse of a significant amount of agricultural plastic residue in an application similar to virgin plastics, contributing in this way to achieve the goals of circular economy policies.

The findings show that less environmental impacts were generated in scenario S1 (post-CLS), the worst was S2 (prior to CLS) and the less impactful material is COEX. It is estimated that the implementation of the CLS resulted in a reduction in 9 of the 13 impact categories analyzed, including a reduction in potential for CC (climate change) between 33% (S3) and 44% (S1). For the other impact categories, the reduction in the potential environmental impacts varies from a minimum of 20% (for the category PMF) to a maximum of 79% (for the impact category of ME). These results indicate that the implementation of the PNRS was environmentally effective, mitigating potential impacts within the boundaries of this study and resulting in the development of a new type of container that is environmentally preferable (COEX). The increase in the residual quantity of pesticide can negatively affect the results and the routes between collection points, central units and EoL facilities can be optimized, reducing the environmental impacts.

Among the steps analyzed, the container manufacturing process (Stage A) is the main contributor to potential environmental impacts. This is due to the energy consumed indicating that manufacturing is the most energy intensive process. COEX was the EPPC material with lower environmental impact, due to the combination of recycled material and virgin raw material, its use saves energy and material resources.

The environmental impacts from Stage B (transportation) are mainly due to the uses of diesel with a high sulfur content. It is shown that the decrease in the number of central units leads to greater distances and consequently to larger impacts. Regarding Stage C, the valorization of EPPC through recycling is the best environmental option for scenarios 1 and 3. Also, recycling ensures (through previous container rinsing) the removal of hazardous residue from the environment. From the sensitivity analysis it can be inferred that shortening the distance between collection points and central units can lead to impact reduction. Another analyzed variable was the amount of pesticide residues remaining in the empty container. The awareness regarding the importance of the correct rinsing of EPPC so that it can be redirected to the recycling plant is a crucial part of the CLS, supported by the PNRS, that needs to be emphasized in order to reduce environmental impacts.

Some limitations are identified in our study. First, the EPPC transport flows considered are based on a logistics model. Second, the modeled incineration process includes energy recovery, which is not yet a Brazilian reality. Third, the EoL of pesticides was modeled as general hazardous waste, without specifying its chemical composition. Lastly, only one path is assumed, i.e. landfilling, for EoL of EPPC when they are not integrated into the CLS.

For future research, it is recommended to widen system boundaries to assess management practices for EPPC at the national level, taking into account the countrywide logistics hindrances that result from the small number of EoL facilities. This will allow for a wider overview on the management practices for EPPC and consequently may lead to the identification of better environmental management practices. Also, the authors recommend a more detailed collection of primary data by the industrial players from the reverse logistics value chain. This will provide the basis to carry on an uncertainty analysis.

Supplementary Material

Supplementary material accompanies this paper.

Table SM1. Distances between Central Units and Collection Points in the State of São Paulo (km) Table SM2. Distance between Central Units and end of life facilities (km) Table SM3. Results of Scenario 1 to transportation from Central Units to Incinerator plants using the impact assessment methodology described in section 2.3 Table SM4. Results of Scenario 1 to transportation from Central Units to Recycler plants using the impact assessment methodology described in section 2.3 Table SM5. Results of Scenario 3 to transportation from Central Units to Incinerator plants using the impact assessment methodology described in section 2.3 Table SM6. Results of Scenario 3 to transportation from Central Units to Recycler plants using the impact assessment methodology described in section 2.3 Figure SM1. Normalization of historical data for the CLS in São Paulo State.This material is available as part of the online article from https://www.scielo.br/j/prod

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001. This work was financially supported by LA/P/0045/2020 (ALiCE), UIDB/00511/2020 and UIDP/00511/2020 (LEPABE), funded by national funds through FCT/MCTES (PIDDAC).The authors acknowledge Santander for the graduate Santander international mobility program grant used during the course of this research.

-

How to cite this article: Marsola, K. B., Oliveira, A. L. R., & Neto, B. (2022). Life cycle assessment of reverse logistics of empty pesticide containers in Brazil: assessment of current and previous management practices. Production, 32, e20210105. https://doi.org/10.1590/0103-6513.20210105.

References

- Agrawal, S., & Singh, R. K. (2019). Analyzing disposition decisions for sustainable reverse logistics: Triple Bottom Line approach. Resources, Conservation and Recycling, 150, 104448. http://dx.doi.org/10.1016/j.resconrec.2019.104448

» http://dx.doi.org/10.1016/j.resconrec.2019.104448 - Altieri, M.A. (2018). Agroecology: the science of sustainable agriculture (2nd ed.). Boca Raton: CRC Press.

- Al-Salem, S. M., Lettieri, P., & Baeyens, J. (2009). Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Management, 29(10), 2625-2643. http://dx.doi.org/10.1016/j.wasman.2009.06.004 PMid:19577459.

» http://dx.doi.org/10.1016/j.wasman.2009.06.004 - Andreoni, V., Saveyn, H. G., & Eder, P. (2015). Polyethylene recycling: waste policy scenario analysis for the EU-27. Journal of Environmental Management, 158, 103-110. http://dx.doi.org/10.1016/j.jenvman.2015.04.036 PMid:25976302.

» http://dx.doi.org/10.1016/j.jenvman.2015.04.036 - Arena, U., Mastellone, M. L., & Perugini, F. (2003). Life cycle assessment of a plastic packaging recycling system. The International Journal of Life Cycle Assessment, 8(2), 92-98. http://dx.doi.org/10.1007/BF02978432

» http://dx.doi.org/10.1007/BF02978432 - Aryan, Y., Yadav, P., & Samadder, S. R. (2019). Life Cycle Assessment of the existing and proposed plastic waste management options in India: a case study. Journal of Cleaner Production, 211, 1268-1283. http://dx.doi.org/10.1016/j.jclepro.2018.11.236

» http://dx.doi.org/10.1016/j.jclepro.2018.11.236 - Barros, M. V., Salvador, R., Piekarski, C. M., & de Francisco, A. C. (2018). Mapping of main research lines concerning life cycle studies on packaging systems in Brazil and in the world. The International Journal of Life Cycle Assessment, 24, 1429-1443. http://dx.doi.org/10.1007/s11367-018-1573-2

» http://dx.doi.org/10.1007/s11367-018-1573-2 - Blanco, I., Loisi, R. V., Sica, C., Schettini, E., & Vox, G. (2018). Agricultural plastic waste mapping using GIS: a case study in Italy. Resources, Conservation and Recycling, 137, 229-242. http://dx.doi.org/10.1016/j.resconrec.2018.06.008

» http://dx.doi.org/10.1016/j.resconrec.2018.06.008 - Brasil. (2010, August 3). Institui a Política Nacional de Resíduos Sólidos; altera a Lei nº 9.605, de 12 de fevereiro de 1998; e dá outras providências (Lei nº 12.305, de 2 de agosto de 2010). Diário Oficial da República Federativa do Brasil. Retrieved in 21 August 2021, from http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm

» http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm - Briassoulis, D., Hiskakis, M., & Babou, E. (2013). Technical specifications for mechanical recycling of agricultural plastic waste. Waste Management, 33(6), 1516-1530. http://dx.doi.org/10.1016/j.wasman.2013.03.004 PMid:23561796.

» http://dx.doi.org/10.1016/j.wasman.2013.03.004 - Briassoulis, D., Hiskakis, M., Karasali, H., & Briassoulis, C. (2014). Design of a European agrochemical plastic packaging waste management scheme - Pilot implementation in Greece. Resources, Conservation and Recycling, 87, 72-88. https://doi.org/10.1016/j.resconrec.2014.03.013

» https://doi.org/10.1016/j.resconrec.2014.03.013 - Companhia Ambiental do Estado de São Paulo – CETESB. (2015). Inventário estadual de resíduos sólidos urbanos 2015. São Paulo.

- Dahlbo, H., Poliakova, V., Mylläri, V., Sahimaa, O., & Anderson, R. (2018). Recycling potential of post-consumer plastic packaging waste in Finland. Waste Management, 71, 52-61. http://dx.doi.org/10.1016/j.wasman.2017.10.033 PMid:29097129.

» http://dx.doi.org/10.1016/j.wasman.2017.10.033 - De Lucia, C., & Pazienza, P. (2019). Market-based tools for a plastic waste reduction policy in agriculture: a case study in the south of Italy. Journal of Environmental Management, 250, 109468. http://dx.doi.org/10.1016/j.jenvman.2019.109468 PMid:31505381.

» http://dx.doi.org/10.1016/j.jenvman.2019.109468 - Empresa de Pesquisa Energética – EPE. (2015). Balanço Energético Nacional 2015. Relatório Síntese: Ano base 2014. Retrieved in 21 August 2021, from https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-127/topico-95/Relatório Síntese 2015.pdf

» https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-127/topico-95/Relatório - Empresa de Pesquisa Energética – EPE. (2018). Balanço Energético Nacional 2018. Relatório Síntese: Ano base 2017. Retrieved in 21 August 2021, from https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-303/topico-397/Relatório Síntese 2018-ab 2017vff.pdf

» https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-303/topico-397/Relatório - European Union. (2010). General guide for Life Cycle Assessment: detailed guidance (1st ed.). Luxembourg. https://doi.org/10.2788/38479

» https://doi.org/10.2788/38479 - Faria, A. C., & Pereira, R. S. (2012). O processo de logística reversa de embalagens de agrotóxicos: um estudo de caso sobre o InpEV. Organizações Rurais & Agroindustriais., 14(1), 127-141. Retrieved in 21 August 2021, from http://www.fca.unesp.br/Home/Extensao/ProjetoColetaSeletiva52/politica_residuos_solidos.pdf

» http://www.fca.unesp.br/Home/Extensao/ProjetoColetaSeletiva52/politica_residuos_solidos.pdf - Grael, P. F. F., Oliveira, L. S. B. L., Oliveira, D. S. B. L., & Bezerra, B. S. (2021). Life cycle inventory and impact assessment for an asphalt pavement road construction: a case study in Brazil. The International Journal of Life Cycle Assessment, 26(2), 402-416. http://dx.doi.org/10.1007/s11367-020-01842-5

» http://dx.doi.org/10.1007/s11367-020-01842-5 - Gu, F., Guo, J., Zhang, W., Summers, P. A., & Hall, P. (2017). From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. The Science of the Total Environment, 601-602, 1192-1207. http://dx.doi.org/10.1016/j.scitotenv.2017.05.278 PMid:28605837.

» http://dx.doi.org/10.1016/j.scitotenv.2017.05.278 - Guinée, J., Gorrée, M., Heijungs, R., Huppes, G., Kleijn, R., Koning, A., van Oers, L., Wegener Sleeswijk, A., Suh, S., Udo de Haes, H. A., Bruijn, H., van Duin, R., & Huijbregts, M. A. (2002). Handbook on life cycle assessment: operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background. Dordrecht: Springer.

- Guyton, K. Z., Loomis, D., Grosse, Y., El Ghissassi, F., Benbrahim-Tallaa, L., Guha, N., Scoccianti, C., Mattock, H., & Straif, K. (2015). Carcinogenicity of tetrachlorvinphos, parathion, malathion, diazinon, and glyphosate. The Lancet. Oncology, 16(5), 490-491. http://dx.doi.org/10.1016/S1470-2045(15)70134-8 PMid:25801782.

» http://dx.doi.org/10.1016/S1470-2045(15)70134-8 - Hauschild, M., & Potting, J. (2005). Spatial differentiation in Life Cycle impact assessment - The EDIP2003 methodology. Danish Environmental Protection Agency, 80, 195.

- Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis – IBAMA. (2019). Histórico de comercialização. Retrieved in 21 August 2021, from http://www.ibama.gov.br/agrotoxicos/relatorios-de-comercializacao-de-agrotoxicos#historicodecomercializacao

» http://www.ibama.gov.br/agrotoxicos/relatorios-de-comercializacao-de-agrotoxicos#historicodecomercializacao - Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2018). Dados atualizados do desempenho e dos impactos do Sistema. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/sistema-campo-limpo/em-numeros/

» http://www.inpev.org.br/sistema-campo-limpo/em-numeros/ - Instituto Nacional de Processamento de Embalagens Vazias – inpEV, Sistema Campo Limpo em Números. (2019). Relatório de sustentabilidade. São Paulo. Retrieved in 21 August 2021, from http://www.inpev.org.br/index

» http://www.inpev.org.br/index - Instituto Nacional de Processamento de Embalagens Vazias – inpEV. (2016). Relatório da sustentabilidade 2016. São Paulo. Retrieved in 21 August 2021, from https://inpev.org.br/relatorio-sustentabilidade/2016/pt/index.html

» https://inpev.org.br/relatorio-sustentabilidade/2016/pt/index.html - International Organization for Standardization – ISO. (2006a). ISO 14040: environmental management: life cycle assessment: principles and framework (testimony of ISO). Genève: ISO.

- International Organization for Standardization – ISO. (2006b). ISO 14044: environmental management: life cycle assessment: requirements and guidelines (testimony of ISO). Genève: ISO.

- Jack, E. P., Powers, T. L., & Skinner, L. (2010). Reverse logistics capabilities: antecedents and cost savings. International Journal of Physical Distribution & Logistics Management, 40(3), 228-246. http://dx.doi.org/10.1108/09600031011035100

» http://dx.doi.org/10.1108/09600031011035100 - Jin, S., Bluemling, B., & Mol, A. P. J. (2018). Mitigating land pollution through pesticide packages: the case of a collection scheme in Rural China. The Science of the Total Environment, 622-623(56), 502-509. http://dx.doi.org/10.1016/j.scitotenv.2017.11.330 PMid:29220774.

» http://dx.doi.org/10.1016/j.scitotenv.2017.11.330 - Lagarda-Leyva, E. A., Morales-Mendoza, L. F., Ríos-Vázquez, N. J., Ayala-Espinoza, A., & Nieblas-Armenta, C. K. (2019). Managing plastic waste from agriculture through reverse logistics and dynamic modeling. Clean Technologies and Environmental Policy, 21(7), 1415-1432. http://dx.doi.org/10.1007/s10098-019-01700-5

» http://dx.doi.org/10.1007/s10098-019-01700-5 - Lazarevic, D., Aoustin, E., Buclet, N., & Brandt, N. (2010). Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resources, Conservation and Recycling, 55(2), 246-259. http://dx.doi.org/10.1016/j.resconrec.2010.09.014

» http://dx.doi.org/10.1016/j.resconrec.2010.09.014 - Marsola, K. B., & Oliveira, A. L. R. (2018). Caracterização da logítica reversa de emabalgens vazias de agroquímicos no Estado de São Paulo. In Anais do XXVI Congresso de Iniciação Científica Unicamp. Campinas: Unicamp. https://doi.org/10.20396/revpibic.v0i0.id

» https://doi.org/10.20396/revpibic.v0i0.id - Mermerta, M., & Babuna, F. G. (2019). Life cycle environmental impact analysis of HDPE packaging materials for different disposal options. In N. Balkaya & S. Guneysu (Eds.), Recycling and reuse approaches for better sustainability, environmental science and engineering (pp. 55-61). Cham: Springer. http://dx.doi.org/10.1007/978-3-319-95888-0_5

» http://dx.doi.org/10.1007/978-3-319-95888-0_5 - Oliveira, A. B. (2019). Avaliação do ciclo de vida de cenários de logística reversa de embalagens de agrotóxicos no Brasil (Tese de doutorado). Universidade Estadual Paulista “Júlio de Mesquita Filho”, Bauru.

- Oliveira, A. B. S., Cantinho, A. M., Souza, G. A., & Chagas, R. S. (2011). Produção, consumo e destinação de embalagens de agrotóxicos no Vale do Paraíba. In XV Encontro Latino Americano de Iniciação Científica e XI Encontro Latino Americano de Pós-graduação. São José dos Campos: Universidade do Vale do Paraíba. Retrieved in 21 August 2021, from http://www.inicepg.univap.br/cd/INIC_2011/anais/arquivos/0126_0067_01.pdf

» http://www.inicepg.univap.br/cd/INIC_2011/anais/arquivos/0126_0067_01.pdf - Oliveira, A. L. R., & Camargo, S. G. C. (2014). Logística reversa de embalagens de agroquímicos: identificação dos dos determinantes de sucesso. Interciencia, 39(11), 780-787.

- Oliveira, M. C., & Magrini, A. (2017). Life cycle assessment of lubricant oil plastic containers in Brazil. Sustainability, 9(4), 576. http://dx.doi.org/10.3390/su9040576

» http://dx.doi.org/10.3390/su9040576 - Perugini, F., Mastellone, M. L., & Arena, U. (2005). A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environment and Progress, 24(2), 137-154. http://dx.doi.org/10.1002/ep.10078

» http://dx.doi.org/10.1002/ep.10078 - Picuno, C., Alassali, A., Sundermann, M., Godosi, Z., Picuno, P., & Kuchta, K. (2020). Decontamination and recycling of agrochemical plastic packaging waste. Journal of Hazardous Materials, 381, 120965. http://dx.doi.org/10.1016/j.jhazmat.2019.120965

» http://dx.doi.org/10.1016/j.jhazmat.2019.120965 - Rentizelas, A., Shpakova, A., & Mašek, O. (2018). Designing an optimised supply network for sustainable conversion of waste agricultural plastics into higher value products. Journal of Cleaner Production, 189, 683-700. http://dx.doi.org/10.1016/j.jclepro.2018.04.104

» http://dx.doi.org/10.1016/j.jclepro.2018.04.104 - Rosenbaum, R. K., Bachmann, T. M., Gold, L. S., Huijbregts, M. A. J., Jolliet, O., Juraske, R., Koehler, A., Larsen, H. F., MacLeod, M., Margni, M., McKone, T. E., Payet, J., Schuhmacher, M., Van De Meent, D., & Hauschild, M. Z. (2008). USEtox - The UNEP-SETAC toxicity model: recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. The International Journal of Life Cycle Assessment, 13(7), 532-546. http://dx.doi.org/10.1007/s11367-008-0038-4

» http://dx.doi.org/10.1007/s11367-008-0038-4 - Souza, R. G., Clímaco, J. C. N., Sant’Anna, P., Rocha, T. B., Valle, R. A. B., & Quelhas, O. L. G. (2016). Sustainability assessment and prioritisation of e-waste management options in Brazil. Waste Management (New York, N.Y.), 57, 46-56. http://dx.doi.org/10.1016/j.wasman.2016.01.034 PMid:26852754.

» http://dx.doi.org/10.1016/j.wasman.2016.01.034 - Stocker, T. F., Qin, D., Plattner, G. K., Tignor, M. M. B., Allen, S. K., Boschung, J., Nauels, A., Xia, Y., Bex, V., & Midgley, P. M. (2013). Climate change 2013: the physical science basis. Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (1586 p.). Cambridge: IPCC.

- Treenate, P., Limphitakphong, N., & Chavalparit, O. (2017). A complete life cycle assessment of high density polyethylene plastic bottle. IOP Conference Series. Materials Science and Engineering, 222(1), 012010. http://dx.doi.org/10.1088/1757-899X/222/1/012010

» http://dx.doi.org/10.1088/1757-899X/222/1/012010 - Urreaga, J. M., Beltrán, F. R., Acosta, J., Aguinaco, T., Fonseca, C., Ochoa, A., Oliet Palá, J. A., González-Sánchez, C., & de la Orden, M. U. (2020). Tube shelters from agricultural plastic waste: an example of circular economy. Journal of Cleaner Production, 268, 122401. http://dx.doi.org/10.1016/j.jclepro.2020.122401

» http://dx.doi.org/10.1016/j.jclepro.2020.122401 - Zappe, A. L., Silva Trentin, A. W., Rodriguez, A. L., & Rodríguez López, D. A. (2015). Diagnóstico da logística reversa de lâmpadas por meio da avaliação de ciclo de vida. Revista CIATEC-UPF, 7(1), 13. http://dx.doi.org/10.5335/ciatec.v7i1.4328

» http://dx.doi.org/10.5335/ciatec.v7i1.4328

Publication Dates

-

Publication in this collection

09 May 2022 -

Date of issue

2022

History

-

Received

26 Aug 2021 -

Accepted

07 Apr 2022