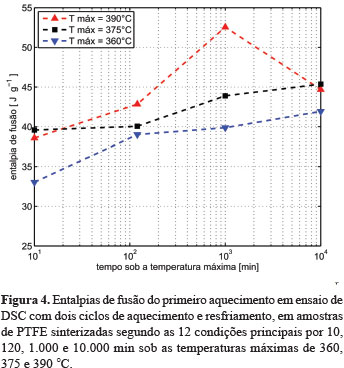

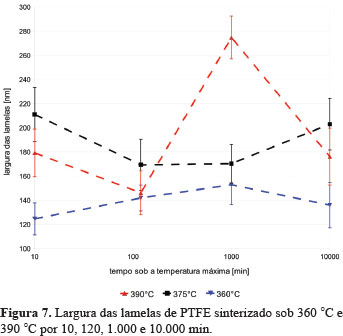

Polytetrafluorethylene (PTFE) is used in a wide range of critical applications because of its outstanding chemical and thermal resistance, low surface energy and special tribological properties. Because of its high melt viscosity, PTFE cannot be processed by traditional extrusion and injection methods. Cold pressing followed by sintering above its melting temperature is the main processing technique. The sintering time is defined according to the dimensions of the manufactured part and may last from a few hours to several days for large parts. Studies of the influence of sintering time and temperature on the PTFE crystalline microstructure are scarce in the scientific literature, being the main objective of this study. PTFE plates were isostatically pressed and sintered at temperatures from 360 ○C and 390 ○C for periods of times between 10 e 10,000 min. Differential Scanning Calorimetry (DSC), measurements of mass loss and density and Scanning Electron Microscopy (SEM) were performed. The results of mass loss indicated that degradation increases with sintering time and temperature. The analysis of the enthalpies of fusion and density measurements indicates indirectly the reduction in molecular weight and increase in the crystallinity degree with increasing sintering temperature and time. The SEM analysis allowed for direct observation of crystalline microstructure, indicating a trend of increasing width for the crystalline lamellae with sintering time and temperature. These data allow one to devise ways to tune the PTFE microstructure during processing, which is useful for the manufacturing of PTFE parts with optimized performance.

PTFE; sintering; thermal degradation; crystallinity