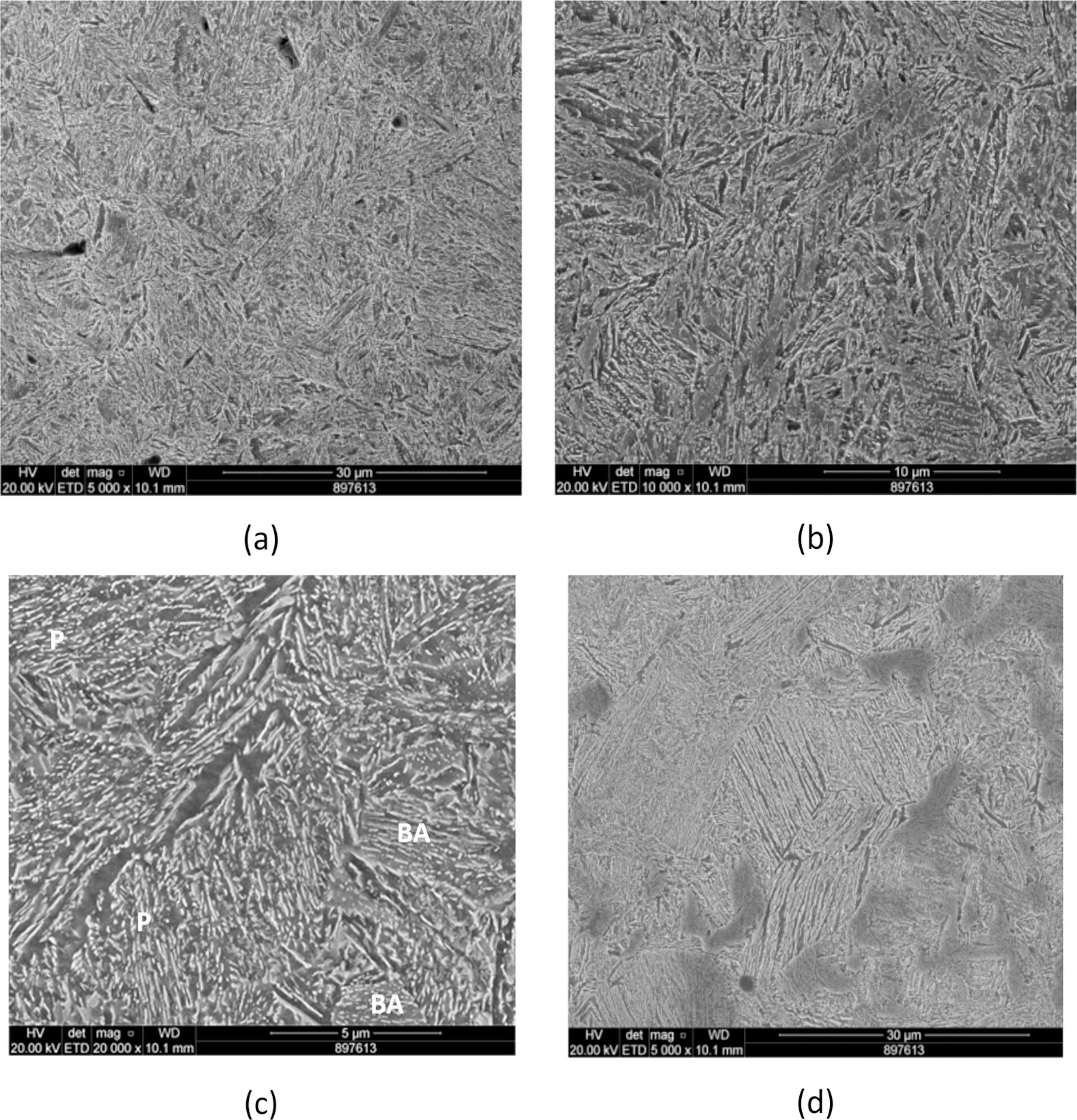

Heavy haul transportation (load over 30 tons/axle), as well as the axle load, has been more and more used in Brazil and worldwide. The stress generated in the wheel-rail contact with loads up to 30 tons/axle is around 760 MPa, which causes premature wear and cracks of conventional wheels (AAR (Association of American Railroads) class C). Microalloyed wheels are fundamental on heavy haul transport, whose main function is to combine high hardness, ductility, and yield strength of the material in order to prevent shelling. The main purpose of this research is to develop a new microalloyed wheel steel with niobium addition that meets all the requirements of the AAR class D material with mixed microstructure composed of pearlite and bainite. The 0.71C/0.020Nb steel developed in this study (Nb material) for railroad achieved the standards required for AAR class D in all mechanical properties, with fracture toughness higher than the usual vanadium microalloyed steel used in comparison. The Continuous Cooling Transformation (CCT) diagram showed the presence of bainite even at very low cooling rate, in the range between 0.3 - 2 °C/s. These cooling rates to form bainite are much lower than those observed in other steels with similar composition.

Keywords:

Microalloyed railway wheel; niobium; heavy haul