Figure 1:

Original signal with upper and lower push and first step of mean value Huang and Shen, (2005Norden E Huang, Samuel S P Shen, (2005) Hilbert-Huang Transform and Its Applications, World Scientific Publishing Co. Pte. Ltd Volume 5).

Figure 2:

Original signal with first step difference with mean value Huang and Shen, (2005Norden E Huang, Samuel S P Shen, (2005) Hilbert-Huang Transform and Its Applications, World Scientific Publishing Co. Pte. Ltd Volume 5).

Figure 3:

The result of first step sifting process Huang and Shen, (2005Norden E Huang, Samuel S P Shen, (2005) Hilbert-Huang Transform and Its Applications, World Scientific Publishing Co. Pte. Ltd Volume 5).

Figure 4:

Original signal with first step residual Huang and Shen, (2005Norden E Huang, Samuel S P Shen, (2005) Hilbert-Huang Transform and Its Applications, World Scientific Publishing Co. Pte. Ltd Volume 5).

Figure 5:

Numerical test signal generated in MATLAB software.

Figure 6:

First cluster decomposed IMF's of numerical test in different frequencies a: 400Hz, b: 200Hz and c: 40Hz.

Figure 7:

the second cluster of IMFs (a, b and c) and general trend (d).

Figure 8:

a: numerical test signal, b: noise, c: noisy numerical test signal and d: magnified comparison of noisy and pure numerical test signal.

Figure 9:

Noise effect on EMD, all first IMF to sixth IMF's are noise in a, b, c, d, e and f, respectively.

Figure 10:

Decomposition of a: first IMF, b: second IMF, c: third IMF and d: fourth IMF.

Figure 11:

FFT spectrum of a: first IMF, b: second IMF, c: third IMF and d: fourth IMF.

Figure 12:

Locations of gears and bearings on input shaft (upper side) and output shaft (lower side).

Figure 13:

Applied engine map for simulation.

Figure 14:

Locations of accessible bearing for data acquisition on simple model.

Figure 15:

Boundary condition for static simulation for choosing mesh length.

Figure 16:

Static simulation result of input gear for mesh independency.

Figure 17:

Convergence of mesh length of mesh independency.

Figure 18:

Meshed model of input gear with length of 0.5 mm.

Figure 19:

a: angular position, b: position and c: acceleration of input shaft.

Figure 20:

a: Noisy no faulty signal and b: noisy no faulty signal in comparison of pure no faulty signal of input shaft.

Figure 21:

Input faulty gear.

Figure 22:

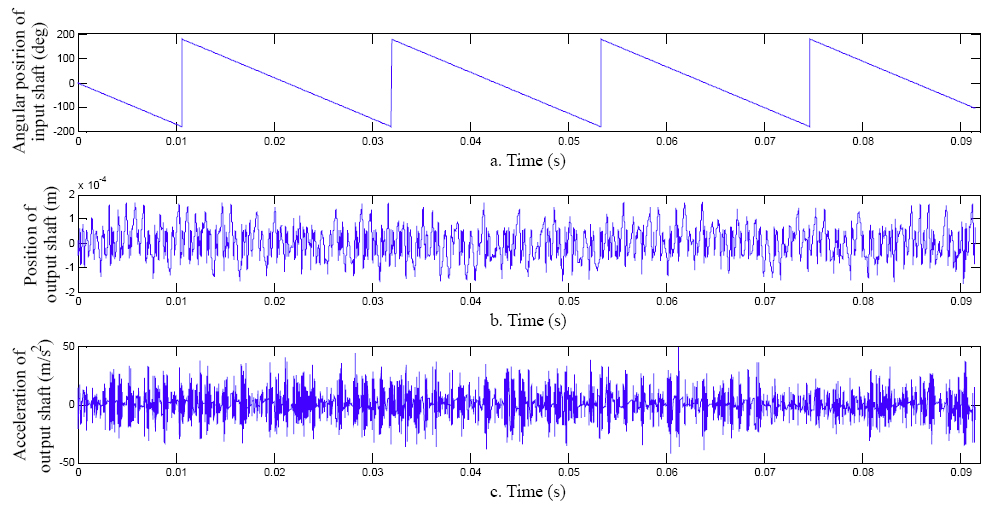

a: angular position, b: Position and c: acceleration of faulty input shaft.

Figure 23:

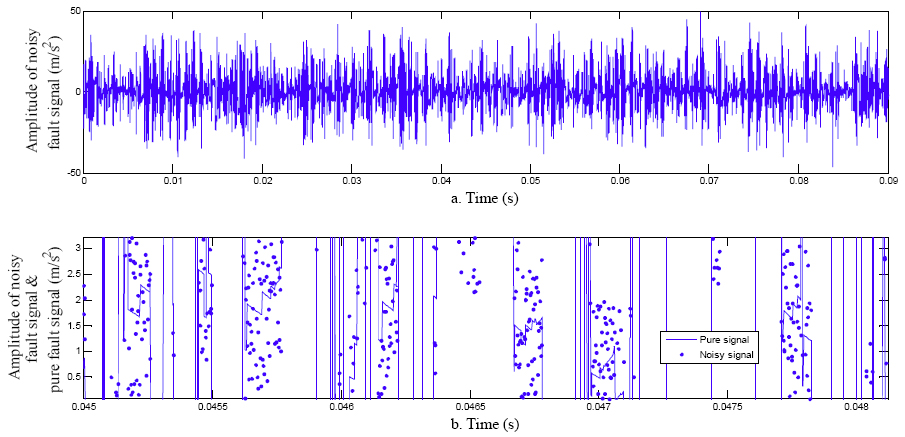

a: Noisy faulty signal and b: noisy faulty signal in comparison of pure faulty signal of faulty input shaft.

Figure 24:

Input partial faulty gear.

Figure 25:

a: angular position, b: Position and c: acceleration of partial faulty input shaft.

Figure 26:

a: Noisy partial faulty signal and b: noisy partial faulty signal in comparison of pure partial faulty signal of faulty input shaft.

Figure 27:

Butterworth low pass filter phase and magnitude in linear system.

Figure 28:

a: zoomed and b: un-zoomed filtered no faulty signal.

Figure 29:

FFT spectrum of no faulty filtered signal.

Figure 30:

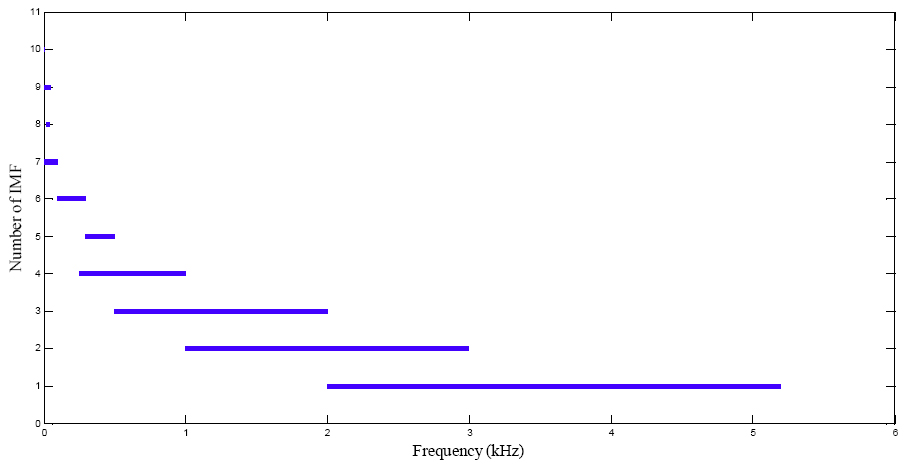

Range of FFT spectrum of each IMF in frequency axis.

Figure 31:

a: first IMF, b: second IMF, c: third IMF and d: fourth IMF of no faulty signal.

Figure 32:

FFT spectrum of a: first IMF, b: second IMF, c: third IMF and d: fourth IMF of no faulty signal.

Figure 33:

a: zoomed and b: un-zoomed filtered one teeth faulty signal.

Figure 34:

FFT spectrum of one teeth faulty filtered signal.

Figure 35:

a: first IMF, b: second IMF, c: third IMF and d: fourth IMF of one teeth faulty signal.

Figure 36:

FFT spectrum of a: first IMF, b: second IMF, c: third IMF and d: fourth IMF of one teeth faulty signal.

Figure 37:

a: filtered signal, b: second IMF and c: FFT spectrum of second IMF of partial faulty signal.